SIM² KU Leuven/ProCESS researchers have corroborated how the use of ultrasound increased the potential of flow crystallization by combining high yield with polymorph control. The work, which was published in Chemical Engineering, was performed in the framework of the European Training Network for Continuous Sonication and Microwave Reactors (COSMIC).

About crystalline compounds

Crystalline compounds are everywhere. Ice, salt, sugar, chocolate are all crystalline compounds. Even pharmaceutical compounds, 90% of them are crystalline. An interesting aspect of crystalline compounds is polymorphism.

Crystals of one compound may exist in different crystal structures called as polymorphs. Although these polymorphs of a compound have the same chemical structure, there are still differences in several properties like melting point, solubility, density, conductivity etc.

This phenomenon is the reason why we see so many different shapes in crystals of snow and why some chocolate tastes better than others. While ice and chocolate are simple examples, this is not the case in medicines, where it can have more serious consequences.

It is crucial for production companies to produce the right polymorph of the medicine at all costs. Achieving this goal requires proper designing, engineering and testing of crystallisers. In addition to that, a high productivity must also be engineered to make a system promising. Technologies like flow reactors and ultrasound can be systematically coupled to crystallisers to achieve these goals.

Flow crystallisers and ultrasound

The goal in this paper is to crystallize the stable polymorph of a pharmaceutical compound called ortho – aminobenzoic acid (o – ABA). This compound has 3 polymorphs – form – I, II and III but the desired form is form – I.

The non-conventional aspects here are the use of a flow crystalliser (instead of conventional batch crystallisers) and the use of ultrasound. Flow crystallisers are much better than batch systems in reducing variability in the product, decreasing cost and improving safety.

Ultrasound on the other hand compliments flow crystallisers by improving mixing, enhancing nucleation rate and reducing induction time.

The main results from the work show that when crystallisation is conducted in the flow crystalliser without ultrasound, the resultant form is always the undesired forms – II and III. Even when seeds of form – I are added the resultant form does not change.

However, when ultrasound is applied pure form – I is produced with seeding and at a high yield of 85%. The assistance from ultrasound, i.e. improved mixing and enhanced nucleation rate, brings about a big change in the activity within the flow crystalliser and helps in producing the desired product with high yield.

Full reference of paper

Mohammed Noorul Hussain, Jeroen Jordens, Simon Kuhn, Leen Braeken, Tom Van Gerven, Ultrasound as a tool for polymorph control and high yield in flow crystallization, Chemical Engineering Journal, https://doi.org/10.1016/j.cej.2020.127272

Acknowledgements

The research leading to these results has received funding from the European Community’s Horizon 2020 Programme [(H2020/2016-2020) under Grant Agreement no. 721290 (MSCA-ETN COSMIC)]. This publication reflects only the authors’ view, exempting the community from any liability. Project website: https://cosmic-etn.eu.

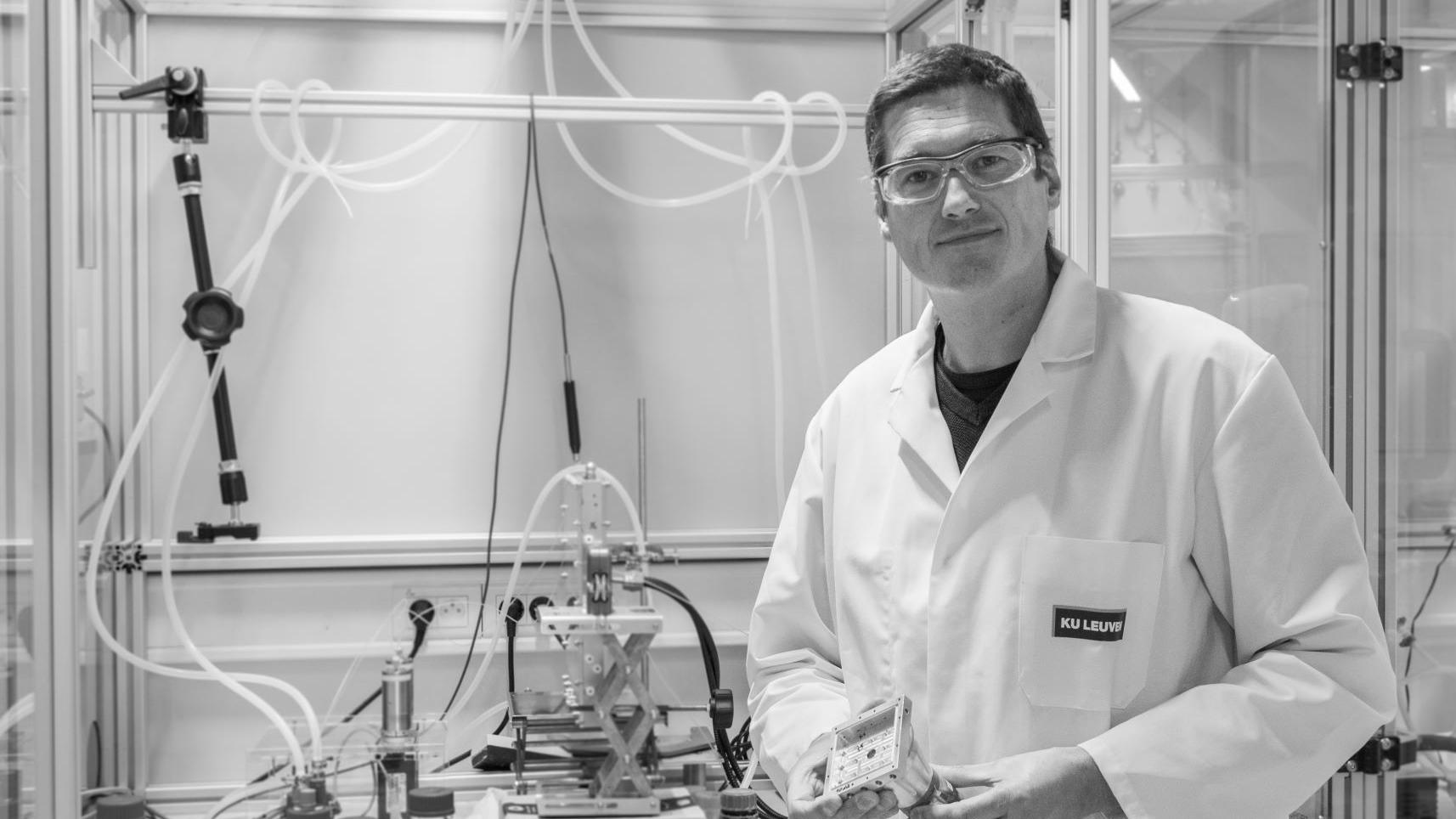

(Featured image: Tom Van Gerven holding an example of a custom-made milli-flow reactor with an off-the-shelf ultrasound transducer attached to it – Credits photo: Elisabeth De Decker]