On November 26, 2019, the KU Leuven Academic Council formally recognised SIM² KU Leuven as one of the 4 flagship “KU Leuven Institutes”. Five months later – while the global COVID-19 pandemic is causing havoc – the new “KU Leuven Institute for Sustainable Metals and Minerals” (SIM²) is up and running. Following a Pre-General Assembly meeting in February 2020, SIM² has fine-tuned its strategic plan and reorganised its research lines and flagship topics, while membership has been formalised. As of April 2020, more than 220 KU Leuven employees are official members of SIM² KU Leuven.

In this article, SIM² KU Leuven Director Peter Tom Jones provides an overview of the current status of the Institute and summarises the main changes and challenges, also in view of the COVID-19 impact on the global supply chains of metals and minerals that are needed for the transition to climate-neutral, circular and resilient economies. Likewise, through this article the new SIM² KU Leuven iconic scheme, which outlines SIM² KU Leuven’s – thermodynamically-proof – view on the role of metals and minerals in the Circular Economy, is launched.

KU Leuven Institutes?

SIM² KU Leuven is one of the four official KU Leuven Institutes that were recently endorsed by the KU Leuven Academic Council. The other Institutes comprise the KU LEUVEN BRAIN INSTITute (BI), the KU LEUVEN CANCER INSTITUTE (LKI) and the KU LEUVEN INSTITute for Artificial Intelligence (Leuven.AI).

The KU Leuven Institutes represent interdisciplinary research with a crucial societal relevance. They focus on subjects that remain important in the long term and rely on an extensive and interdisciplinary network. They are the ideal basis for the exchange of expertise across disciplinary boundaries, opening up promising new prospects. KU Leuven Rector Luc Sels:

“For the University, the KU Leuven Institutes are a way to highlight certain focal points in research – a strategic instrument, in other words. For the outside world, they’re a recognisable point of contact in an important research field. And for the individual researcher, they are a form of recognition, a signpost towards organisational security, and a kind of intellectual home base – alongside the faculties and departments, which, of course, will continue doing their work unabatedly and keep playing an important role.”

About COVID-19 and a resilient supply of raw materials

Early 2020 the global Corona/COVID-19 crisis started spreading around the planet. The outbreak forced governments worldwide to send billions of people in lockdown; mid-April 2020 already more than 150,000 persons succumbed to the deadly virus. Beyond the devastating health impact, COVID-19 is having very substantial impacts on raw material supply chains globally, as mining and processing operations were and are suspended.

If the Corona crisis can teach us anything about the raw materials conundrum it is this: raw materials cannot be taken for granted. Our modern, interconnected global economy is far more vulnerable than many thought. Taking into account that the materials, which are required for electric vehicles, batteries, renewable energy and several other key enabling technologies for the transition to a climate-neutral economy, are dominated by just a limited amount of non-EU countries, it is clear that (the resource-poor) Europe finds itself in a highly vulnerable situation.

We need more resilience to avoid to replace Europe’s reliance on fossil fuels with a reliance on non-energy (critical) raw materials. Hence, securing a diverse, sustainable and resilient supply of (critical) raw materials to the EU is a vital, strategic, long-term issue for Europe, as recently acknowledged by the EC in the European Green Deal (COM(2019)640) and A New Industrial Strategy for Europe (COM(2020)102).

SIM² KU Leuven’s contribution to a resilient supply of raw materials

This Grand Societal Challenge is directly addressed by SIM² KU Leuven, whose fine-tuned mission is:

“to develop, organise and implement problem-driven, science-deep research and future-oriented education, contributing to the environmentally friendly production and recycling of metals, minerals and engineered materials, supporting the transition to a climate-friendly, circular-economy.

“SIM² KU Leuven, therefore, designs, researches and exploits selective and efficient processes for the exploration, extraction, recovery, recycling and refining of (base and critical) metals and minerals, as well as for the upcycling of primary and secondary resources and the re- and demanufacturing of End-of-Life complex metal-containing products.”

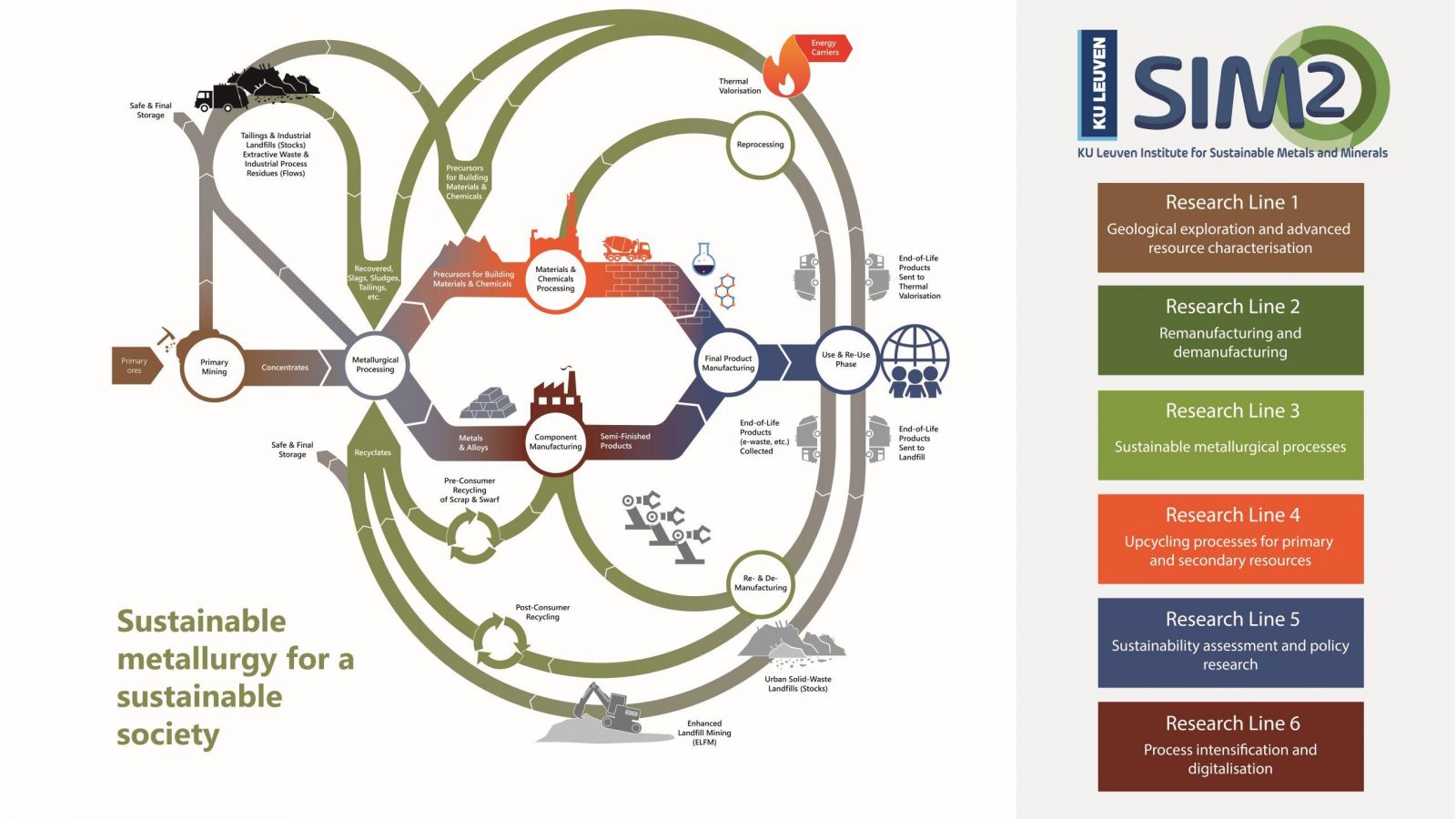

Figure 1: Scope of SIM² KU Leuven research on sustainable metallurgy for a climate-neutral, circular, resilient economy (McGuiness & Jones, April 2020)

Sustainable metallurgy for a sustainable society

In order to provide the metals and minerals that are needed for the transition to resilient, climate-neutral economies, SIM² KU Leuven has developed its own, thermodynamically-based view on the “circular economy”, which goes far beyond the often simplistic and outright naïve circular economy drawings that can be found on the worldwide web.

SIM² KU Leuven’s take of the Circular Economy is depicted in Figure 1, which is the result of a concerted discussion amongst several SIM² KU Leuven members. The figure highlights that SIM² KU Leuven tries to smartly close as many metals and minerals loops as possible, while also realising there is a need for (responsible) primary mining of a multitude of speciality metals (e.g. rare earths, cobalt, lithium) that are in high demand for e-mobility, renewable energy storage etc.

These metals are not yet present in sufficient amounts in the technosphere, implying that even 100% recycling will not be enough in view of satisfying the rapidly growing demand for these metals to be used in diverse clean technologies.

Although there is a clear need for primary mining, we also need to acknowledge that many mining activities in the world are associated with dirty environmental practices, atrocious labour violations and widespread corruption. Mining is often a story of “graft and exploitation”. A new type of mining, also in Europe, is required, allowing us to go beyond the Not-In-My-Backyard-Approach. That’s the reason why SIM² KU Leuven’s extended mission statement includes the following section:

“SIM² KU Leuven assesses and advances the environmental gains and the economic feasibility of the developed flow sheets. In order to support the Social License to Operate for the associated industrial activities, SIM² KU Leuven pro-actively engages with external stakeholders, including civil society groups and local communities. SIM² KU Leuven also assesses the potential health and environmental impacts of (primary) mining activities to support the transition to responsible mining.”

In contrast with many simplistic Circular Economy drawings, SIM² KU Leuven acknowledges that there are inevitable losses during metals and minerals processing and that, in some cases, certain (hazardous) residues need final (safe) storage solutions rather than being recycled. This view was corroborated by the highly respected metallurgist Prof. Markus Reuter (TU BAF/HZDR, Germany) during the EU-wide event “The green transition challenged by the metal supply chain” (Flemish Parliament, Brussels, March 12, 2020):

“The inconvenient truth of the circular economy is that the nexus energy–materials is a downward spiral. The best we can do is to mitigate this spiral and not to go down too fast.”

Finally, SIM² KU Leuven is not blind for our historic legacy: a comprehensive Circular Economy view should not just deal with the waste flows of the present but should also find an answer for the waste stocks of the past. Hence, SIM² KU Leuven has been an ambassador for the Enhanced Landfill Mining agenda, which targets both stocks of extractive waste/industrial residues (including Waste-to-Energy residues) and Urban Solid Waste/Municipal Solid Waste. Only then can we genuinely claim to overcome the Dark Side of the Circular Economy (Figure 2).

Figure 2: Video Dark Side of The Circular Economy

Six formal Research Lines

Figure 1 also highlights the six formal Research Lines within the KU Leuven Institute for Sustainable Metals and Minerals. As a result of the transition from the informal SIM² KU Leuven cluster (which already exists since 2011) to the formal KU Leuven Institut, one new Research Line has been created (RL2: “Remanufacturing and Demanufacturing”)) while the old Research Lines 2 and 3 were merged into the new RL3: “Sustainable Metallurgical Processes”.

The new RL2 is led by Dr. Jef Peeters. The rationale for this new Research Line is that in a more circular economy the objective is to keep products, components and materials at their highest level of utility for the longest time possible:

“To achieve this the deployment of Industry 4.0 technologies (see also Research Line 6 of SIM² KU Leuven), such as artificial intelligence and robotics dismantling and sorting, are investigated for the splitting of products into their components or composing materials in support of reuse, repair, repurposing, remanufacturing and/or high-end recycling. (…)”

The new RL3 focuses on “Sustainable Metallurgical Processes”. The Research comprises both pyro/electrometallurgical and hydro/solvometallurgical unit processes. The explicit goal is to develop processes with the lowest possible footprint in terms of CO2 emissions, energy, water and/or use of chemicals. To corroborate the advantages the processes are benchmarked with state-of-the-art industrial processes. This Research Line is fully synchonised with the clean energy and smart moblity targets set forth in the European Green Deal (EC,COM(2019)640) and A New Industrial Strategy for Europe (EC,COM(2020)102).

Another key novelty that SIM² KU Leuven has integrated Prof. Erik Smolders (Department of Earth & Environmental Sciences) into the team. This is reflected in the new RL5 flagship topic “Risk assessment of metals and metalloids in the environment”. The scope of this topic is as follows:

“The environmental risk of metals and metalloids, such as cobalt or cadmium, is controlled by the speciation of these compounds. This means that total concentrations are only poor indicators of risk. SIM² KU Leuven performs the risk assessment of metals and metalloids in the environment and in the food chain. The assessments can be desk-top based or use environmental monitoring and testing of speciation and toxicity. (…)”

An example of the relevance of this work is the recent paper by Smolders and colleagues on the sustainability of artisanal mining of cobalt in DR Congo, which was published in Nature Sustainability.

SIM² KU Leuven in numbers

In the period February – March 2020, the SIM² KU Leuven group reached out to other KU Leuven colleagues, research groups and departments to join the new Institute. A fine-tuned governance and membership model was set up. Currently, the new Institute comprises more than 220 KU Leuven employees, including approximately 30 professors and senior research managers, 48 postdocs and research experts, 130 Phd students and several project managers.

The membership is truly interdisciplinary as researchers are involved from a wide variety of research groups and departments, ranging from Materials Engineering to Mechanical Engineering, Civil and Architectural Engineering, Bio-Engineering, Chemical Engineering, Chemistry, Earth & Environmental Sciences, Economics and Corporate Sustainability, as well as Law. A full overview of the SIM² KU Leuven General Assembly Members can be found here.

Figure 3: SIM² KU Leuven Pre-General Assembly, February 24, 2020

SIM² KU Leuven and the future

The formal recognition as a KU Leuven Institute will act as a catalyst for the SIM² KU Leuven team to collaborate even more intensively with its core partners in Flanders (cf. “Flanders Metals Valley”), Belgium & Europe (e.g. EIT RawMaterials) and beyond (e.g. CR³) to help realising its mission and vision (“A society that uses its resources in an efficient, effective and sustainable way”).

Given the gargantuan challenges that will need to be tackled in the 21st Century – post-COVID-19 – it is clear that SIM² KU Leuven will have a busy agenda. We look forward to it and reach out to our colleagues worldwide to facilitate the transition to the climate-neutral, circular and resilient economies of the future.