The lifecycle engineering (LCE) research group (SIM² – KU Leuven) of the KU Leuven has developed a method that enables robotic demanufacturing system to learn from prior demanufacturing actions performed on identical product models. In the presented research, the developed generic retrieval system has been demonstrated to have significant potential to improve the robustness and efficiency of robotic demanufacturing of laptops. The work was published in the journal “Resources, Conservation and Recycling”.

Recent developments in robotic demanufacturing raise the potential to increase the cost-efficiency of recycling and recovering resources from Waste of Electrical and Electronic Equipment (WEEE). However, the adoption of robotic demanufacturing for mixed WEEE streams requires tailored instructions for every product model. Considering the large variation in product models, it is not expected to be feasible in the coming decade to rely only on computer vision technologies to define these product model tailored instructions that are essential for robust, time-efficient and in depth robotic demanufacturing.

YODO: You Only Demanufacture Once

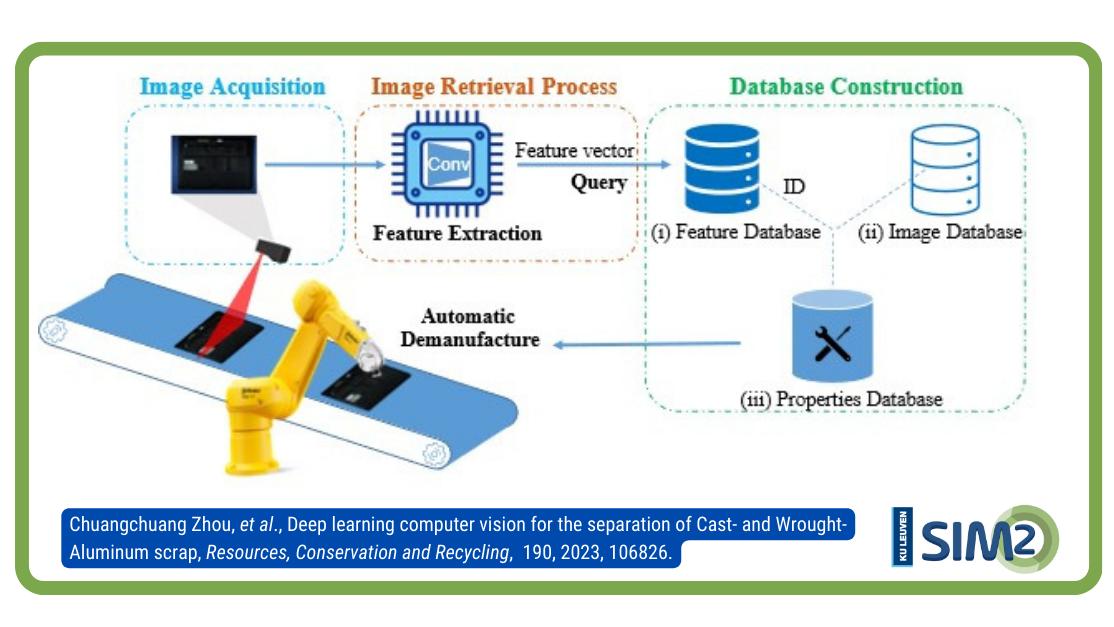

Therefore, the presented research developed a generic retrieval system named You Only Demanufacture Once (YODO). This content-based image retrieval (CBIR) system is able to identify the product model and retrieve product model-specific demanufacturing instructions. The system compares the visual features represented on a color image of the WEEE with a database of descriptions of previously imaged WEEE to find a match, and to define in case that no match was found that the analyzed product model is new to the system.

.png)

Laptop model identification

The performance of YODO is evaluated with a case study for laptop model identification, where a large dataset is created including 4089 images of a representative laptop waste stream of which images of these laptops ware randomly presented to the system. The results demonstrate a top-1 retrieval mean average precision (mAP) of 93.75%.

After running YODO on 3600 laptops, the system learned 1079 unique product models, and the presented results show already an 85% chance that the next laptop presented to the system has been priorly registered in the database, allowing the retrieval of relevant information for robotic demanufacturing.

This allows to conclude that a fast learning rate can be achieved when considering that only in Belgium over a million of laptops are discarded every year. Hence, the YODO system is found to encompass significant potential to support the robotic demanufacturing by making the system (self) learning.

In the framework of the SUDE 4.0 project, the KU Leuven Life Cycle Engineering group has also demonstrated the feasibility of integrating this YODO system in a pilot system for laptop demanufacturing, as shown here: https://www.linkedin.com/feed/update/urn:li:activity:6967407186532524032?utm_source=share&utm_medium=member_desktop

Youtube video: https://www.youtube.com/watch?v=enTciLFhtNY

Complete reference of the paper

Chuangchuang Zhou, Wouter Sterkens, Dillam Jossue Díaz-Romero, Isiah Zaplana, Jef Peeters, You Only Demanufacture Once (YODO): WEEE retrieval using unsupervised learning, Resources, Conservation and Recycling, Volume 190, 2023, 106826, ISSN 0921-3449, https://doi.org/10.1016/j.resconrec.2022.106826.

LCE research group and EAVISE Research Group