On March 5, 2018, in the presence of the Flemish Minister for Nature, Environment and Agriculture, Joke Schauvliege, Metallo officially presented its new, state-of-the-art plasma furnace for transforming low-grade resources into metals and minerals. Metallo, a strategic long-term research partner for SIM² KU Leuven and a Beneficiary in the EU H2020 ETN SOCRATES project, can be proud to launch this new “non-transferred arc plasma” furnace, which will be the largest of its kind in the world. It shows there’s a bright and green future for plasma-based pyrometallurgy, offering a valuable instrument for the “new metallurgical toolbox of the 21st Century”! In the article below you can read more about the background of this new investment in Beerse, near Antwerp and the type of plasma used. Congratulations Metallo! (PTJ, 13-3-2018, Leuven)

A world’s first in recycling at Metallo

On March 5th, press and dignitaries gathered together at the site of Metallo Group in Beerse. Flemish minister Joke Schauvliege cut the ribbon for a brand-new, unique plasma oven. CEO of the Metallo Group, Dirk Vandenberghe, announced proudly: ‘With this new installation we recycle low grade materials in an innovative way into high grade metals and minerals.’ This event is a benchmark in the history of the company. Not only is the technology groundbreaking, the underlying thought also marks a small quantum leap in the perception of raw materials. This is how Metallo helps to form the future of the circular economy.

Metallo has been in existence for almost a hundred years. With the opening of this innovative installation the recycling company shows that they are ready for the future. In Dirk Vandenberghe’s view, Metallo proves their ambition with this: ‘We confirm that we play a worldwide pioneering role in terms of the circular economy.’

He continues: ‘Our region is known as the Flanders Metal Valley. This is how that has grown historically: a large network of companies was able to treat each other’s residual materials. This was how a valuable symbiosis arose. Because of that, Flanders is a pioneer in the world of recycling. Metallo now takes the lead and develops groundbreaking technology themselves to be able to covert low grade secondary materials even more into new raw materials. That shows the devotion to our mission and also our urge for renewal. The determination of our employees and the guts of our investors made this milestone possible.’

Vandenberghe also emphasizes the engagement of the employees: ‘In less than five years we went from idea to realization of the project. The opening of the new installation is a benchmark in the history of our company, of which this generation of employees can be rightfully proud. Together we pushed the boundaries. Our plasma oven is unique after all: it is the largest oven in the world, of this specific type. The innovative installation brings us a step closer to our goal: adding value the circular economy, by converting low grade secondary materials into high grade metals and minerals.’

In short: behind the historical walls of the site in Beerse a driven team is working with cutting-edge technology about innovation and sustainable value creation.

Crushing orange peels

This is how Metallo formulates answers to the fundamental questions of our time: how do we, as a society, deal with the fact that our primary raw materials are becoming scarcer? How can we organize our economy circular and sustainable?

Mathias Chintinne, the man who in his function of R&D Manager with Metallo Group, helped push the development and the building of the new plasma oven into the right direction, applies himself to difficult questions like this every day. As an engineer he comes up with solutions for challenges like: how can we recuperate the materials as much as possible so that they can be used again?

Chintinne outlines the idea behind the new plasma oven with the use of a striking example: ‘Compare our process with the squeezing out of an orange. Imagine that the orange is the secondary material, our raw material. At Metallo we refine the non-ferro metals from the secondary material, let’s say the “juice” from the orange. The peel is the residual product with a low metal content. The orange press is the unique process of Metallo Group with which we have been able for years to still squeeze a little more juice from the peel of the orange. Now we take a radical next step. With our new installation we now make sure that the orange peel itself becomes a valuable product. Nobody has ever done that before.’

Air run through lightning

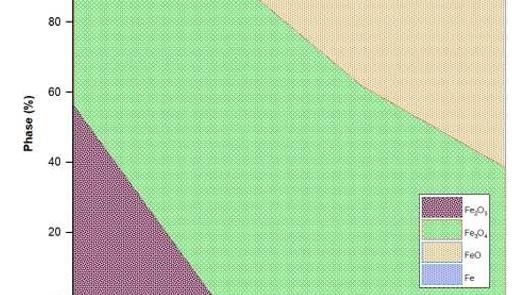

To make that possible in a profitable way, Metallo invested in innovative technology: a plasma oven. But what exactly is plasma? Chintinne: ‘Plasma is formed when a gas ionizes. Because of an energy source or electrical voltage, the gas molecules will split, and the gas achieves different characteristics: it becomes electrically conductive, heat conductive. It no longer is a gas, but a completely new aggregation state: plasma. Familiar examples are neon lights, lightning or the sun.’

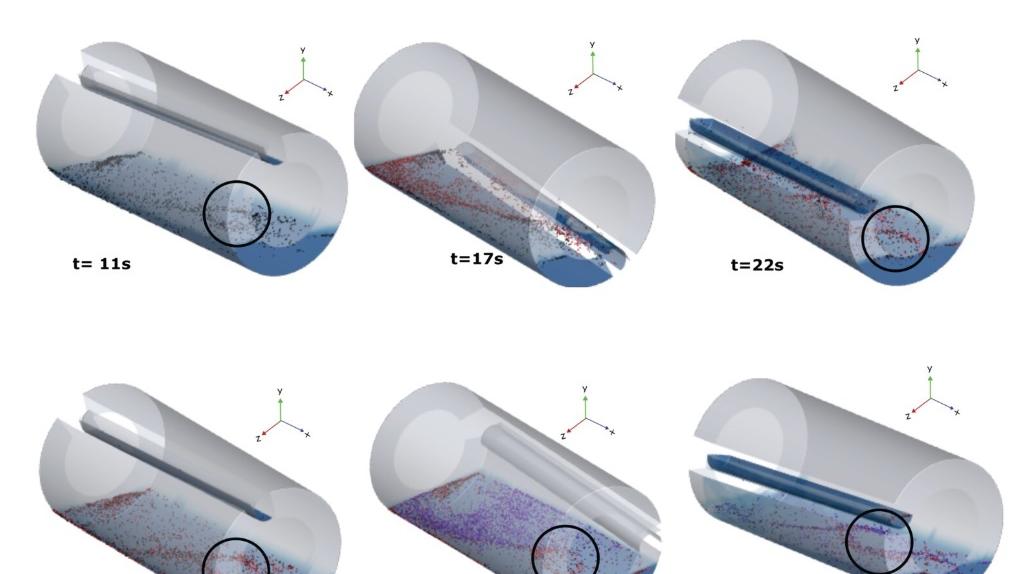

Plasma was already in use at industrial processes. But not in the way or on the scale that Metallo does it now. Metallo built the largest non-transferred arc plasma oven in the world. That is quite a mouthful. Chintinne: ‘We provide a continuous arc of flame, compare that with a permanent lightning and we blow air through that. Because of the lightning the air becomes extremely hot and it ionizes partly. This plasma of 5000°C we blow into the reactor to evaporate the metals from materials from our other processes. This is how they are purified to usable metals and minerals.’

Chintinne gives three well thought out arguments to take up the pioneer role and to choose for plasma technology: ‘Firstly because of the energy source. The plasma oven runs on electricity, unlike the more conventional ovens. This gives the installation the potential to run on green energy once the conversion to renewable energy sources has been made. Secondly, this technology is now ready to be applied at a large scale. Thirdly, plasma has the characteristic that you compress a lot of energy into a limited amount of gas. Because of the compactness of the installation in comparison to other technologies, the impact on the environment is also more restricted.

100% natural

Besides the recycled materials there is another end product that comes out of the plasma oven: a synthetic mineral, with several application possibilities. Here it is of crucial importance that the policy makers create a good framework for the further development of the circular economy, is the opinion of Inge Maes, Director Sustainable Enterprise with Metallo Group: ‘The presence of the Flemish Minister for Nature, Environment and Agriculture Joke Schauvliege at the opening of the new installation is a beautiful recognition for our efforts. And it shows that the policy has an eye for the further development of the circular economy. That is necessary, because we still see strong differences between sectors. We wield – often unconsciously – different criteria when it concerns recycling.’

Maes gives a striking example: ‘Everybody knows that the choice for recycled paper is the most sustainable, environment sensitive option. Many people prefer recycled paper with an eco-label. But in the construction industry they prefer gravel from the river Meuse to produce concrete. That gravel should then be ‘100% natural’. Our synthetic material can replace that gravel, so we no longer need to dredge the rivers. So, in itself it is the most ecological choice. Sensitization from the policy can help to grow the minds.’

‘For our planet it is also of the utmost importance that we start to rethink terminology such as waste and raw materials’, opines Maes. ‘Policy makers face the challenge, together with us: how can we make sure that raw materials don’t get lost? That they will not be categorized unnecessarily as ‘waste’ and are dumped somewhere, but that they are recuperated as much as possible? At Metallo more than 500 proud employees support that mission every day. They hope that policy makers will continue to work on a fruitful framework to realize a sustainable, circular economy.’

More information about Metallo: visit their website here