On June 8, 2022, Panagiotis Xanthopoulos (SOLVOMET Group, SIM2 KU Leuven Institute and Early Stage Researcher in the MSCA-ETN SULTAN project) obtained his PhD degree in Chemistry. He successfully defended his PhD thesis entitled “Recovery of metal ions from dilute aqueous solutions by ion flotation”.

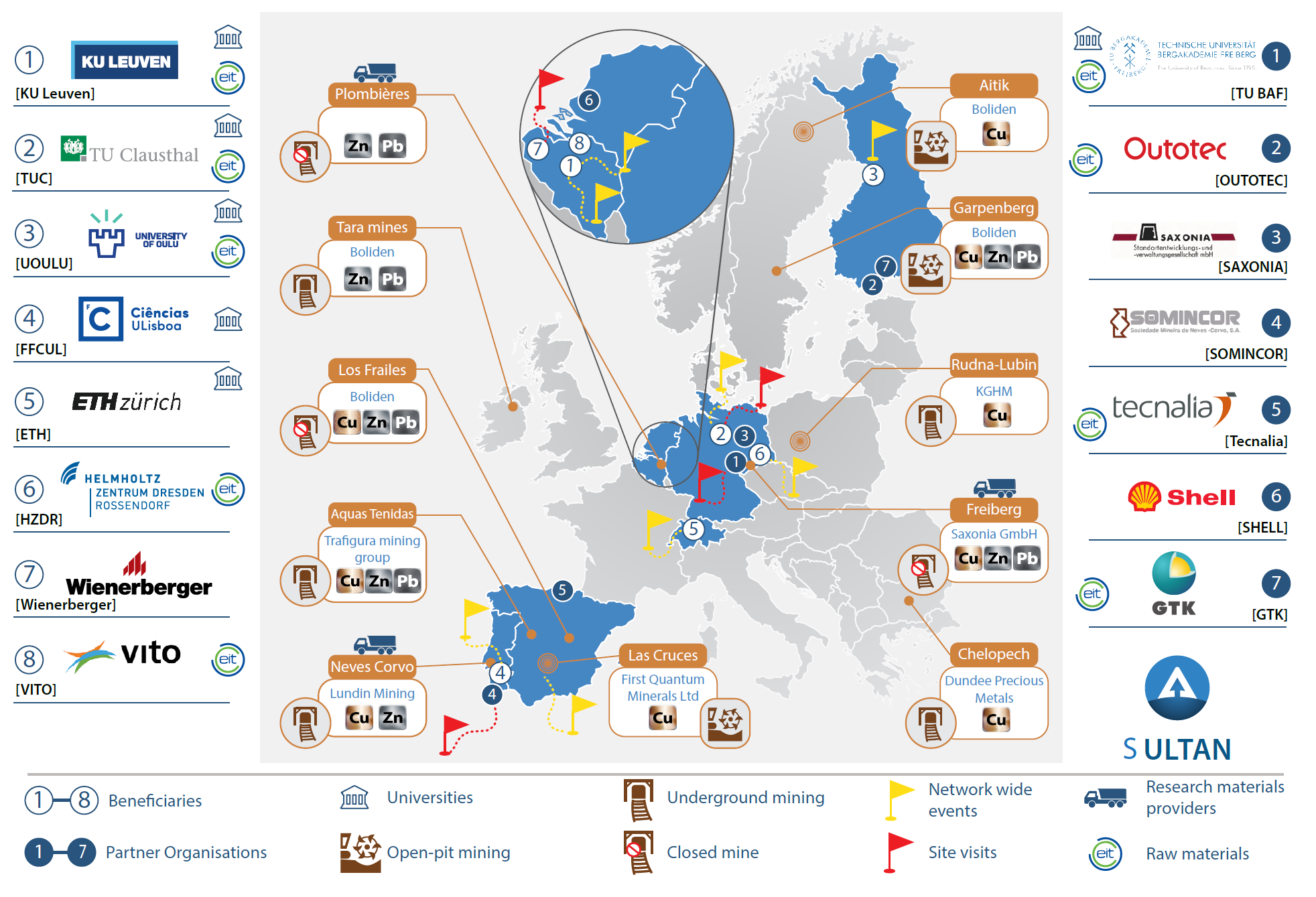

Panagiotis Xanthopoulos carried out his PhD in the SOLVOMET group of Prof. Dr. Koen Binnemans, his supervisor. The PhD research was part of the H2020-MSCA-ETN SULTAN project, the EU Training Network targeting the remediation and reprocessing of sulphidic mining wastes. Dr. Xanthopoulos will continue his career in the SOLVOMET group, as post-doctoral researcher and he will investigate the metal extraction and recovery from secondary low-grade mineral resources, end-of-life products and ores.

The popularised summary of the PhD research along with list of publications are available below; the full text of the thesis will be made publicly available in due time.

Abstract

Metals are increasingly important for our modern societies as they find a plethora of applications in electricity, transportation, construction, automobile/space/aircraft industries and many more. To date, the standard metal production can be divided into three principle activities: mining, mineral processing and metallurgical extraction. However, this approach results into the generation of vast amounts of liquid, solid or gaseous waste and depletion of natural resources.

Tailings are fine grained mixtures of unwanted material derived from the mineral processing of ores. Sulphidic tailings represent the largest waste stream of tailings in Europe: rough estimations reveal a fresh production of more than 500 Mt per year and more than 28,000 Mt stockpiled in inactive mining facilities (historic tailings). The management of sulfidic tailing entails a series of environmental risks, ranging from acid mine drainage generation to dam failures. The development of new metallurgical systems, which can efficiently extract and recover the remaining valuable metal content and valorise the residual matrix, is perhaps the most ideal solution to minimise their potential environmental impacts. As a result, sulphidic tailings will no longer be considered as waste but as low-grade metal resources.

Due to the concentrations of valuable metals in these resources, their leaching will generate dilute leachates from which metal recovery is a challenge. Ion flotation is an adsorptive bubble separation technique that is based on differences in surface activity and it is capable for recovering or removing metals from dilute aqueous solutions.

In this technique, surfactants are added to an aqueous solution and compressed air or nitrogen gas is sparged through the solution, to generate a mobile gas-liquid interface. The targeted metal ions are adsorbed to this interface due to interactions with the oppositely charged polar head of the surfactant. The surfactant-metal complex is concentrated to a stable foam phase as the bubbles ascend to the surface of the solution.

Due to its simplicity and fast operation, the technique of ion flotation has attracted researchers’ attention as an alternative detoxification or hydrometallurgical operation. Nevertheless, current advances examine the efficiency of the technique in single or binary aqueous systems and neglect the development of a closed-loop ion flotation flow sheets with regeneration of the collector. As a consequence, the industrial implementation of this technique to hydrometallurgical operations is limited.

The objectives of this PhD thesis aimed to contribute into two different ways: (1) the implementation of the technique for the detoxification of trace concentrations of heavy metals by ion flotation as well as the recovery of valuable metals from dilute ammoniacal and chloride leachates derived from low-grade mineral resources and (2) the development of a method in order to strip the collected metals from the loaded foam and regenerate and recycle the collectors used in ion flotation.

Firstly, the removal of trace concentrations of cadmium, zinc and manganese from simulated mine waters was investigated by using sodium dodecyl sulfate as collector and triethylenetetramine as auxiliary ligand. At optimised conditions, it was possible to simultaneous remove these contaminants in one step almost quantitatively.

Secondly, the recovery of copper from dilute copper-zinc ammoniacal leachates of microwave-roasted sulphidic tailings was studied. The addition of sodium dodecyl sulfate selectively concentrated copper over zinc to the foam phase as colloidal tetraammine copper(II) dodecyl sulfate.

Thirdly, a novel solvometallurgical approach was successfully developed for the stripping of copper from the loaded foam and the regeneration and reuse of sodium dodecyl sulfate.

Finally, the recovery of lead from dilute lead-zinc chloride leachates from end-of-life products was investigated. The differences in the charge of lead and zinc chloride complexes resulted into a selective separation of lead over zinc with cetyltrimethylammonium bromide as collector.

The experimental results obtained from these studies were found to be very promising, as it is clearly indicated that ion flotation has a high potential as an alternative detoxification and hydrometallurgical technique.

List of peer-reviewed publications in scientific journals

- P. Xanthopoulos, K. Binnemans. Removal of cadmium, zinc and manganese from dilute aqueous solutions by foam separation. J. Sustain. Metall. 7, 78–86 (2021). DOI: 10.1007/s40831-020-00322-2

- P. Xanthopoulos, D. Kalebić, N. Kamariah, J. Busse, W. Dehaen, J. Spooren, K. Binnemans. Recovery of Copper from Ammoniacal Leachates by Ion Flotation. Journal of Sustainable Metallurgy, 2021, 7, 1552–1564. DOI: 10.1007/s40831-021-00363-1

- P. Xanthopoulos, K. Binnemans, Closing the Loop in Ion Flotation: Recovery of Copper, Regeneration and Reuse of Collector from the Foam Phase by a Solvometallurgical Process. Journal of Sustainable Metalllurgy, 2021, 7, 1565–1574. DOI: 10.1007/s40831-021-00463-y.

- S. Bevandić, P. Xanthopoulos, P. Muchez, Chemical Leaching of Sulfidic Mining Waste, Plombières Tailings Pond, Eastern Belgium: Insights from a Mineralogical Approach. Journal of Sustainable Metalllurgy, 2021, 7, 1444–1455. DOI: 10.1007/s40831-021-00445-0

- P. Xanthopoulos, S. Bevandić, J. Spooren, K. Binnemans, F. Kukurugya, Recovery of copper, zinc and lead from photovoltaic panel residue. RSC Advances, 2022, 12, 2351-2360. DOI: 10.1039/D1RA09268E

- N. Kamariah, D. Kalebić, P. Xanthopoulos, R. Blannin, F. P. Araujo, S. Koelewijn, W. Dehaen, K. Binnemans, J. Spooren. Conventional versus Microwave-Assisted Roasting of Sulfidic Tailings: Mineralogical Transformation and Metals Leaching Behavior. Minerals Engineering. 2022, 183, 107587. DOI: 10.1016/j.mineng.2022.107587.