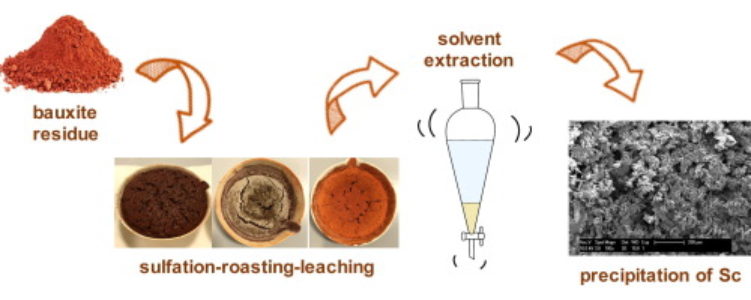

Researchers at KU Leuven developed a process to obtain leachates from bauxite residue (red mud) with a much higher concentration of scandium than can be achieved via conventional leaching with acids. The process uses a combination of sulfation-roasting-leaching and solvent extraction with the hydrophobic ionic liquid betainium bis(trifluoromethylsulfonyl)imide, [Hbet][Tf2N]. The scandium concentration in the leachate was increased by applying multistage leaching, during which the obtained leachate is contacted multiple times with freshly roasted material.

Full reference: B. Onghena, C.R. Borra, T. Van Gerven, K. Binnemans, Recovery of scandium from sulfation-roasted leachates of bauxite residue by solvent extraction with the ionic liquid betainium bis(trifluoromethylsulfonyl)imide, Separation and Purification Technology, 176, 208–219 (2017), doi: http://dx.doi.org/10.1016/j.seppur.2016.12.009

Download pdf here

See also two other papers on rare-earth recovery and red mud:

- The SIM² KU Leuven review paper on rare-earth recovery from industrial process residues: Koen Binnemans, Peter Tom Jones, Bart Blanpain, Tom Van Gerven, Yiannis Pontikes, Towards zero-waste valorisation of rare-earth-containing industrial process residues: a critical review, Journal of Cleaner Production, 99 (2015) 17-38. Download here.

- Chenna Rao Borra and colleagues published a landmark review paper on red mud valorisation in the Journal of Sustainable Metallurgy. Full reference: C.R. Borra, B. Blanpain, Y. Pontikes, K. Binnemans, T. Van Gerven,”Recovery of Rare Earths and Other Valuable Metals From Bauxite Residue (Red Mud): A Review”, Journal of Sustainable Metallurgy, DOI 10.1007/s40831-016-0068-2. Download here