SOLVOMET members have developed a new process for the valorization of the leaching residue of the zinc roast-leach-electrowin process using methanesulfonic acid (MSA). This residue accounts for 0.3 tons per ton of produced zinc, and its valorization strategy focuses on the selective recovery of lead (because of the high concentration, 18 wt%) and silver (because of its high economic value). The work has been published open access, and it’s a clear example of the advantages of solvometallurgy.

Methanesulfonic acid (MSA) has proven again to be a suitable lixiviant for the recovery of valuable metals. Within the SMART project, the SOLVOMET group has developed a solvometallurgical process for the selective recovery of lead and silver from industrial residues.

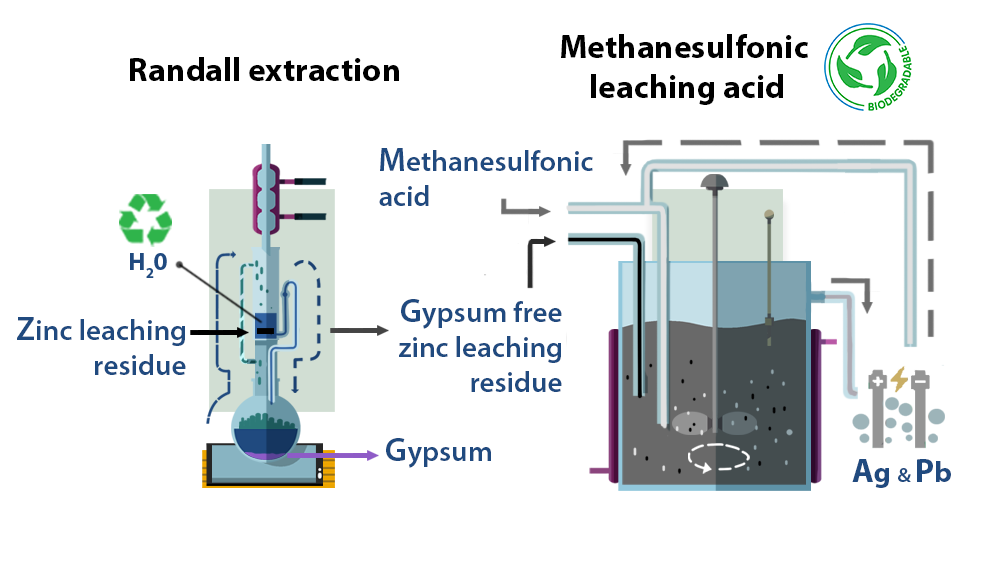

Randall extraction as pretreatment

SOLVOMET researchers show than Randall extraction, which is a continious Soxhlet extraction, is of potential interest for the selective recovery of mineral phases. In fact, 85% of the calcium present in the zinc leaching residue could be recovered via Randall extraction using water, which could be continuously re-used. The obtained by-product was pure gypsum, which can be sold for construction purposes. This pretreatment reduces the subsequent lixiviant requirements and improves the overall performance of the leaching process.

Leaching with MSA

MSA was selected as lixiviant due to the high solubility of lead and silver methanesulfonate salts compared to other inorganic lead and silver salts. More than 80% of the lead and the silver could be leached at moderate conditions with remarkable selectivity. The selectivity, which can be drastically tuned by changing the water content of MSA, proves that solvometallurgical approaches are a promising substitute to hydrometallurgy. The SOLVOMET group is compromised with the development of sustainable industrial processes: MSA combines the characteristics of a green solvent (low volatility, a low toxicity and biodegradability) with a low price. Both characteristics facilitate the industrial implementation of the process. MSA has been previously shown to be a suitable lixiviant for the recovery of metals from wastes.

Full reference paper

Recovery of lead and silver from Zinc Leaching Residue using methanesulfonic acid. Nerea Rodriguez Rodriguez, Bieke Onghena, Koen Binnemans, ACS Sustainable Chemistry & Engineering 2019, 7, 24, 19807-19815. DOI: 10.1021/acssuschemeng.9b05116

Acknowledgements

The Strategic Initiative Materials in Flanders (SIM) is gratefully acknowledged for the financial support (SBO-SMART: Sustainable Metal Extraction from Tailings) with Grant No. HBC.2016.0456. The Dutch Organization for Scientific Research (NWO) is acknowledged for the financial support (grant number: ECHO.11.TD.006).