Hans Vanhove and colleagues from the Department of Mechanical Engineering, KU Leuven have a new article on the local reinforcement of titanium sheet by means of GTAW droplet deposition for threaded connectionsin. The paper is published in Materials Research Proceedings from Material Forming – ESAFORM 2024.

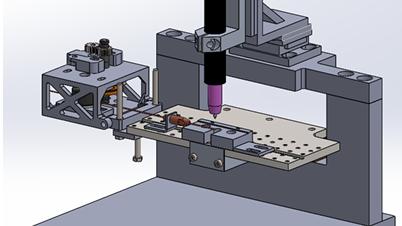

Making threaded connections to thin metal sheets requires locally thickening of the sheet in order to provide enough thread length for a structurally sound connection. Shaped Metal Deposition processes like Gas Tungsten Arc Welding (GTAW) allow to locally build-up material in order to provide thickness for a sufficient length of thread engagement. This publication describes the research towards local thickening of a titanium sheet by means of pulsed Tungsten Inert Gas (TIG) droplet deposition, aimed at creating threaded holes for thin shelled bone fracture fixation plates. The influence of current, weld time and amount of filler material on droplet diameter and height is studied.

Reference

Material Forming – ESAFORM 2024, Materials Research Forum LLC Materials Research Proceedings 41 (2024) 363-370, https://doi.org/10.21741/9781644903131-41

Acknowledgement

This paper was based on the thesis work of Oskar Vandenbroecke. The research on droplet deposition for medical implants is performed in the framework of the KUL, STIFF project.