Prof. Xing Yang is an Associate Professor in the ProcESS division, Department of Chemical Engineering at KU Leuven, where she leads a research group focusing on the development of smart responsive separation processes for solute purification and resource recovery, combining experimental and multi-scale simulation tools towards process intensification. Lithium refining, as well as the integration of solvent extraction and membrane technology, are two of her favourite topics. In the present SIM² interview you get to know more about Yang’s research activities and her advice concerning technology upscaling and… getting babies to sleep.

You have recently been appointed as professor at KU Leuven. Congratulations. What is the research area that you will develop in Leuven?

Thank you! Guided by the principle of Energy-Efficient Separation Systems for Sustainability (2E3S), one of my main research lines to be expanded at KU Leuven is the development of smart, responsive separation membranes and hybrid processes for solute purification and resource recovery, tackling challenges in the Environment-Resource-Health Nexus under the Circular Economy Initiatives. The target applications include value capturing from metal & mineral containing processing & waste streams. For example, the recovery of rare earth metals from metallurgical wastes, and lithium from brines and Li-containing wastes.

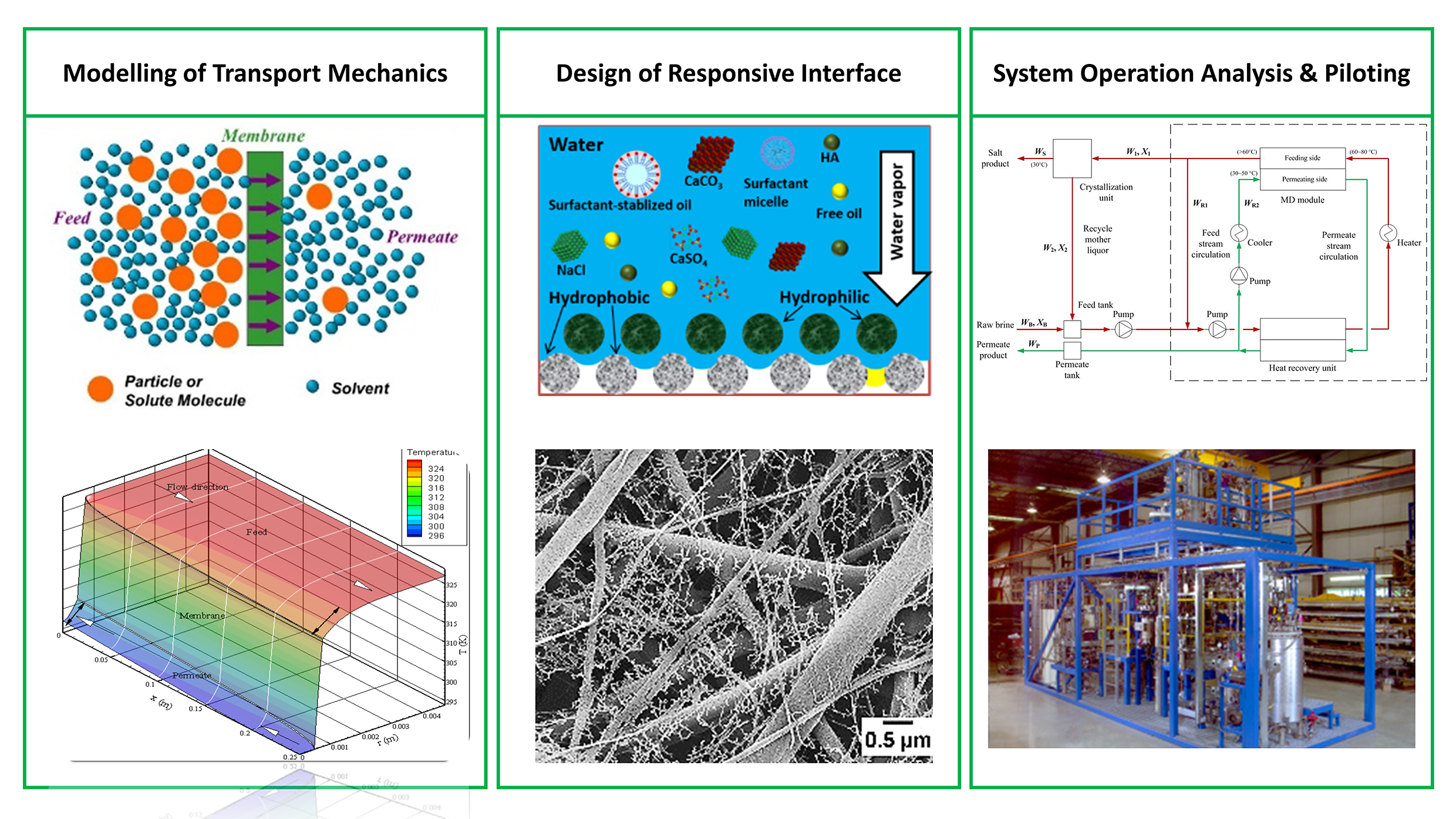

We combine the power of experimental research and process system engineering via multi-scale mathematical modelling to identify performance limiting factors and achieve process intensification with minimal inputs and maximal output. We are dedicated to both bench-scale research to design novel materials/applications/systems, and applied research in large scale for resource recovery and environmental applications.

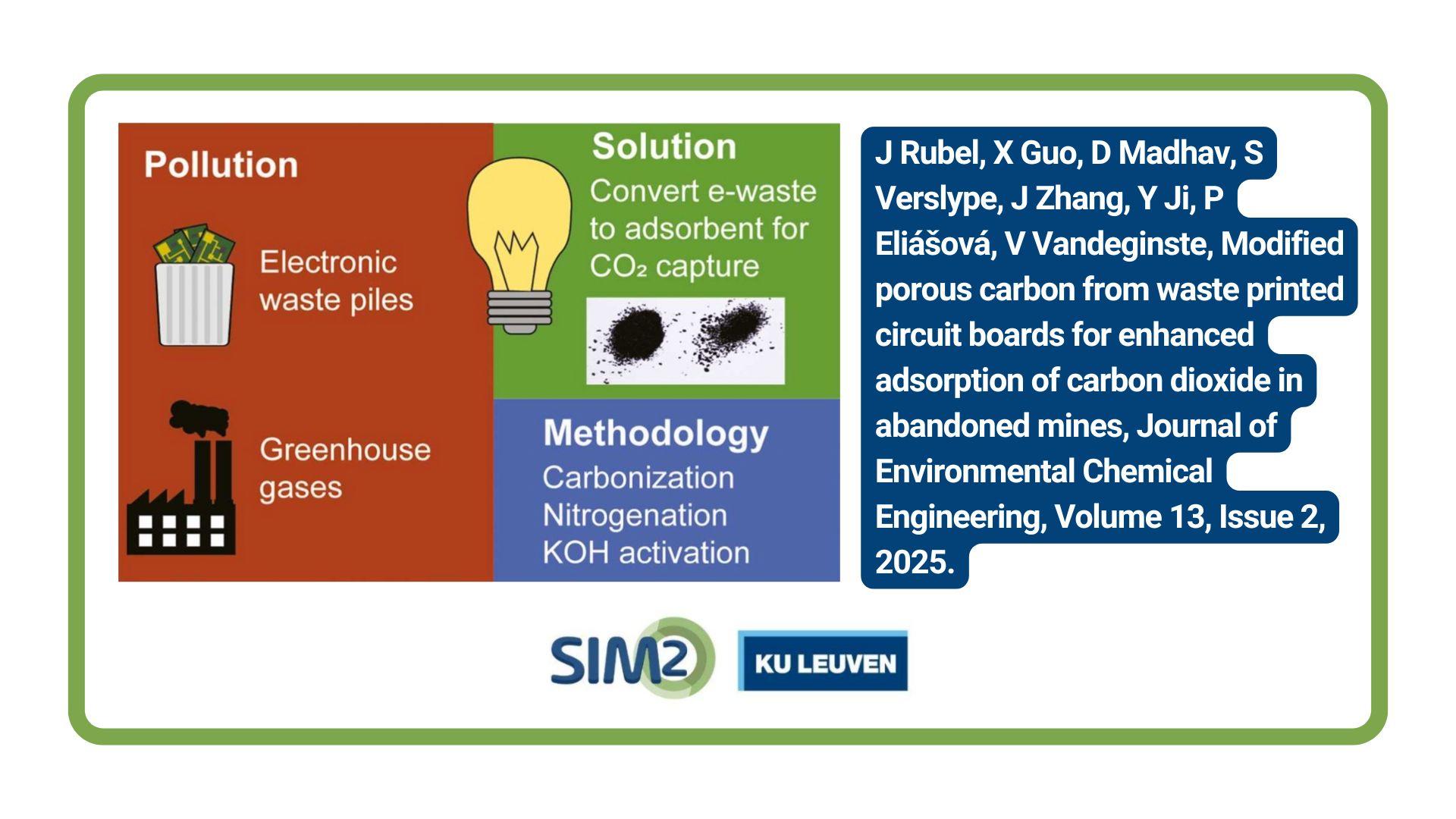

During the past years the European Commission has expressed its ambition to make the EU climate neutral by 2050. As we all know, the metallurgical industry is highly energy- and CO2-intensive. How is your research aligned with these developments?

Indeed, the processing of raw materials to produce metals faces major challenges due to extensive energy consumption and waste generation. Being a massive challenge in the world of a deteriorating environment and depleting natural resources, the removal of critical contaminants and recovery of valuable compounds from wastes has strategic importance to sustainability in Europe and worldwide.

Particularly in the metallurgical industry, the enormous wastes generated and discharged to the environment during metal processing have led to vast CO2 emission levels and serious water pollution, demanding energy- and cost-intensive treatments. For example, the Belgian metallurgy industry produces billions of tonnes of wastewater per year, e.g., 800 kL of water is needed to produce 1 kg of steel, leading to significant loss of valuable metals in water and causing severe damage to our natural water ways. Such an unsustainable situation has urged researchers and engineers to deliver innovation and low-cost solutions to the community and industry.

For the last 10 years I have been dedicated to resource recovery from chemically-challenging waste streams using low-carbon hybrid membrane technology. In the years to come, I would like to continue in the strong research environment of KU Leuven and contribute to the development of “resource and energy recycling” technologies in the metal and mineral supply chain.

Before arriving in Leuven, you worked in China, Singapore and, for the last six years, Australia. There you worked with mining companies. What were the main challenges for these companies? Will you continue this work?

Interestingly, I always seem to have a connection with industrial companies in my research career, starting with my PhD project and postdoctoral experience in Singapore. The fact that I tend to understand industry problems quite quickly has helped me to expand the research partnership with water, mining and mineral companies through the Institute for Sustainable Industries and liveable cities at Victoria University, focusing on the recovery of mineral and rare earth metals from laboratory-scale studies towards technology piloting, ultimately driving research impacts in the mining and mineral production technologies.

I can see that the main challenge though faced by these companies is how to achieve sustainable production and reduced process complexity. Most current technologies are extremely intensive in terms of chemical, water and energy consumption, waste generation and CO2 emissions. For example, as one of the world’s major suppliers of lithium, Australia produces LiOH·H2O in an unsustainable way, by burning coal. Also, in the purification steps, the main challenge is to improve the selectivity between solutes of interests and impurities to achieve high-purity products.

I will continue this research direction but using very different strategies and from a wider angle, such as the incorporation of smart materials to achieve novel chemistry and tailored structure to facilitate high selectivity and process throughput, developing an in-depth knowledge framework to connect the missing dots between kinetics – interface – synergistic transport, and expanding into life-cycle-analysis (LCA) to assist the development of resource recovery technologies.

The European Commission has recently published its fourth list of Critical Raw Materials (CRM) and has launched the somewhat Orwellian term of “open strategic autonomy”. In its new list, lithium has now been officially identified as a “Critical Raw Material”. Do you plan to work on lithium extraction and refining? How can your expertise help here?

Yes. I will continue to work on lithium extraction and refining. Lithium is one of most interesting and perhaps also a very challenging element to separate, for example the separation of Li+/Mg2+ and Li+/Na+ ions from brines. My previous approach mainly utilised process control strategies assisted with solubility chemistry and kinetics, which did not yield desirable selectivity.

Thus, in our group, further research will be focused on the design of smart membranes for highly selective alkali metal ion separation including electro-driven and adsorptive membranes; while our expertise on modeling comes in handy to understand the transport mechanisms, the engineering of separation devices such as membrane modules and exergy analysis of integrated separation systems, providing a holistic platform for lithium separation.

In SIM² there is a lot of work being done on solvent extraction. Where do you place membrane separations in relation to solvent extraction? Do you see opportunities for complementarity between the two technologies?

This is a good question. I can see there is a great opportunity to cross the bridge and build complementary multi-disciplinary research between solvent extraction and membrane separation. In fact, my past project experiences entailed the integration of membrane separation, solvent extraction and ion exchange to achieve the purification of rare earth metals from mining streams, where a membrane was used as an intensification step to enhance the separation efficiency, particularly when the concentrations of solutes of interest were low.

In this way the process becomes economically justifiable. In the near future, we are going to demonstrate the design of extractive and adsorptive membranes, where novel extractants are immobilised stably into the membrane matrix, to combine the respective advantages of solvent extraction and membrane separation. This area of research requires a lot of knowledge on extractant chemistry and synergistic extraction. Therefore, complementary collaboration with experts on solvent extraction becomes essential.

You have worked before both on more fundamental aspects and on scale up of technologies. Which challenges do you see for scale up of new technologies?

Indeed, I have been very lucky to experience how a technology was scaled up from the lab to the field. I would say the main challenge and often least familiar to researchers for up-scaling is the non-linear relationship between bench and large-scale operation, which requires a lot of verification and trial-and-error to close the gap.

Another challenge would be the constant demand to justify the economic benefits of a new technology, to industry partners, investors, and stakeholders. It is essential to always be able to demonstrate tangible results and products. Most importantly, you have to speak their language to get them to understand the technical details, your research capacity and strong potential of the new technology to climb up the TRL ladder. Lastly, the skills to pull together a multi-functional team and manage expectations from different parties are critical for the success of technology up-scaling.

On a more personal level, are there any game-changing moments in your research career? I am referring to moments which made you fundamentally rethink your research focus and/or strategy?

I tend to think very carefully before making a big move. There were two game-changing moments during my career. One was when I decided to pursue a PhD after working in Bayer as a process engineer for 1 year, it was the part of me that always looked for new challenges but I guess industry jobs are rather routine. It was also because that I was fascinated by the research of my PhD supervisors Prof. Rong Wang and Prof. Tony Fane. Then I became one of the first PhD students at Singapore Membrane Technology Centre in NTU that was founded in 2008.

The second moment was when I decided to leave Australia and start a new chapter of my career at KU Leuven, the epiphany came even before the date that my appointment was offered. It felt like home already when I first visited Leuven in 2019. I was amazed by the research capacity and collaborative culture in KU Leuven, where offers a lot of academic freedom and I bond very easily with colleagues.

Also, Belgium has a strong industry of chemical processing, energy production and health science, exactly where I have the vision to create the next generation membrane platform for. I know it was a huge decision to move across the borders, particularly with the big family and during COVID-19. But I trust my intuition. I am extremely excited about building my team at KU Leuven in the coming decades.

What attracts you in research? How do you stay motivated?

As mentioned, I was once working in an industry company. But I decided to do my PhD in membrane science and technology and stay in academia since then. When I look back, I think the beauty of research is the need to constantly deal with new challenges, which are driven by creativity and desire to solve real world problems. My research has always been in the intersection of fundamentals and technology translation, which is always driven by impacts – how to provide an effective and cross-disciplinary solution to de-bottleneck and push the boundaries of current separation technologies?

I hold the same beliefs for mentoring junior researchers and students. I am very passionate on education, which is also my motivation to stay in academia. When I see the sparkles of love from my students’ eyes when talking about their research work, I know they are in love and will stay self-motivated.

Finally, just for our readers to know, what is the strangest talent you have?

Believe it or not, I am extremely talented at sleep training babies. All my three children slept through 12-hour straight within 12 weeks, consistently and without much effort! I also offer free consultation to friends who have newborns and help parents to regain their sleep. My door is always open if you face such challenges.

Thank you for this interview. We wish you all the best in your research endeavours.

[Interview: Peter Tom Jones & Tom Van Gerven]

Biography Prof. Xing Yang

Prof. Yang (LinkedIn profile) is currently an associate professor at the ProcESS division in the Department of Chemical Engineering, KU Leuven. She is a trained Chemical Engineer through her Bachelor study in Zhejiang University (China), Master in Chinese Academy of Sciences and PhD in Nanyang Technological University (Singapore). Prior to joining KU Leuven, she worked at Victoria University (Australia) for six years and was a Senior Research Fellow / Lecturer, also held a joint position between Deakin University and Victoria University (2019 – 2020). Prof. Yang has more than 10 years of interdisciplinary research experience focusing on the development of functional membranes and hybrid separation systems for resource recovery and bioseparation. Her expertise includes process intensification and integration for designing energy-efficient hybrid membrane systems combining experimental and multiscale numerical modelling. Her research has attracted several major Australian Research Council grants and industry funding, with extensive experience in both fundamental research and technology piloting. Yang's Research Group: URL

Some key papers by Prof. Xing Yang in the field of process intensification with hybrid membrane processes

- G Guan, Hanwen Lou, Chenglong Yao, Jing Li, X Yang*, Achieving Sustainable Operation for Hypersaline Membrane Distillation applications: A Novel Strategy based on the Critical Reynolds Number, Desalination (2021), 499, p114833. https://doi.org/10.1016/j.desal.2020.114833

- W Chen, T Xiao, X Yang*, Tuning the Pore Structure of Poly(vinylidene fluoride) Membrane for Efficient Oil/Water Separation: A Novel Vapor Induced Phase Separation Method based on Lower Critical Solution Temperature system, Industrial & Engineering Chemistry Research (2020), 59 (33), p14947. https://doi.org/10.1021/acs.iecr.0c02462 (X.Y. featured as “I&EC Research 2020 Class of Influential Researchers”)

- A Vanangamudi, L F. Dumée, M Duke, X Yang*, Thermo-responsive Nanofibrous Composite Membranes for Efficient Self-Cleaning of Protein Foulants, Journal of Membrane Science (2019), 574, p309. https://doi.org/10.1016/j.memsci.2018.12.086

- A Vanangamudi, D Saeki, L F. Dumée, M Duke, T Vasiljevic, H Matsuyama, X Yang*, Surface-Engineered Biocatalytic Composite Membranes for Reduced Protein Fouling and Self-Cleaning, ACS Applied Materials & Interfaces, 2018, 10 (32), p 27477. https://doi.org/10.1021/acsami.8b07945

- X. Yang*, H.J. Pang, J.H. Zhang, A. Liubinas, M. Duke, Sustainable waste water deammonification by vacuum membrane distillation without pH adjustment: role of water chemistry, Chemical Engineering Journal, 328 (2017), p884. https://doi.org/10.1016/j.cej.2017.07.104

- GQ. Guan, X. Yang*, R. Wang, A G. Fane, Evaluation of Heat Utilization in Membrane Distillation Desalination System Integrated with Heat Recovery, Desalination, 366(2015), p.80 https://doi.org/10.1016/j.desal.2015.01.013

- T Xiao, P Wang, X Yang*, X Cai, Ji Lu, Fabrication and characterization of novel asymmetric Polyvinylidene fluoride (PVDF) membranes by nonsolvent-thermally induced phase separation (NTIPS) method for membrane distillation applications, Journal of Membrane Science (2015), 489, p160. https://doi.org/10.1016/j.memsci.2015.03.081

- GZ. Chen, X. Yang, R. Wang, A G. Fane, Performance enhancement and scaling control with gas bubbling in a direct contact membrane distillation. Desalination, 308(2013): p. 47. https://doi.org/10.1016/j.desal.2012.07.018

- X. Yang, H. Yu, R. Wang, A G. Fane, Analysis on the effect of turbulence promoters in hollow fiber membrane distillation module via computational fluid dynamic (CFD) simulations, Journal of Membrane of Science, (415–416)(2012): p. 758 https://doi.org/10.1016/j.memsci.2012.05.067

- X. Yang, R. Wang, A G. Fane, Novel designs for improving the performance of hollow fiber membrane distillation modules, Journal of Membrane of Science, 384 (1-2) (2011):p. 52 https://doi.org/10.1016/j.memsci.2011.09.007

Want to know more about SIM²?

SIM² KU Leuven is the KU Leuven Institute for Sustainable Metals and Minerals (SIM² in short). SIM² is one of the six official KU Leuven Institutes that were endorsed by the KU Leuven Academic Council. SIM² has more than 240 members, coming from a wide range of (interdisciplinary) research groups and departments at KU Leuven. SIM²’s missions is “to develop, organise & implement problem-driven, science-deep research & future-oriented education, contributing to the environmentally friendly production & recycling of metals, minerals & engineered materials, supporting (…) a climate-friendly, circular-economy”. Read more in this featured article in the KU Leuven Magazine Geniaal.

Follow SIM² on LinkedIn: https://www.linkedin.com/company/18118889

Interviews with other SIM² colleagues: https://kuleuven.sim2.be/meet-our-colleagues/