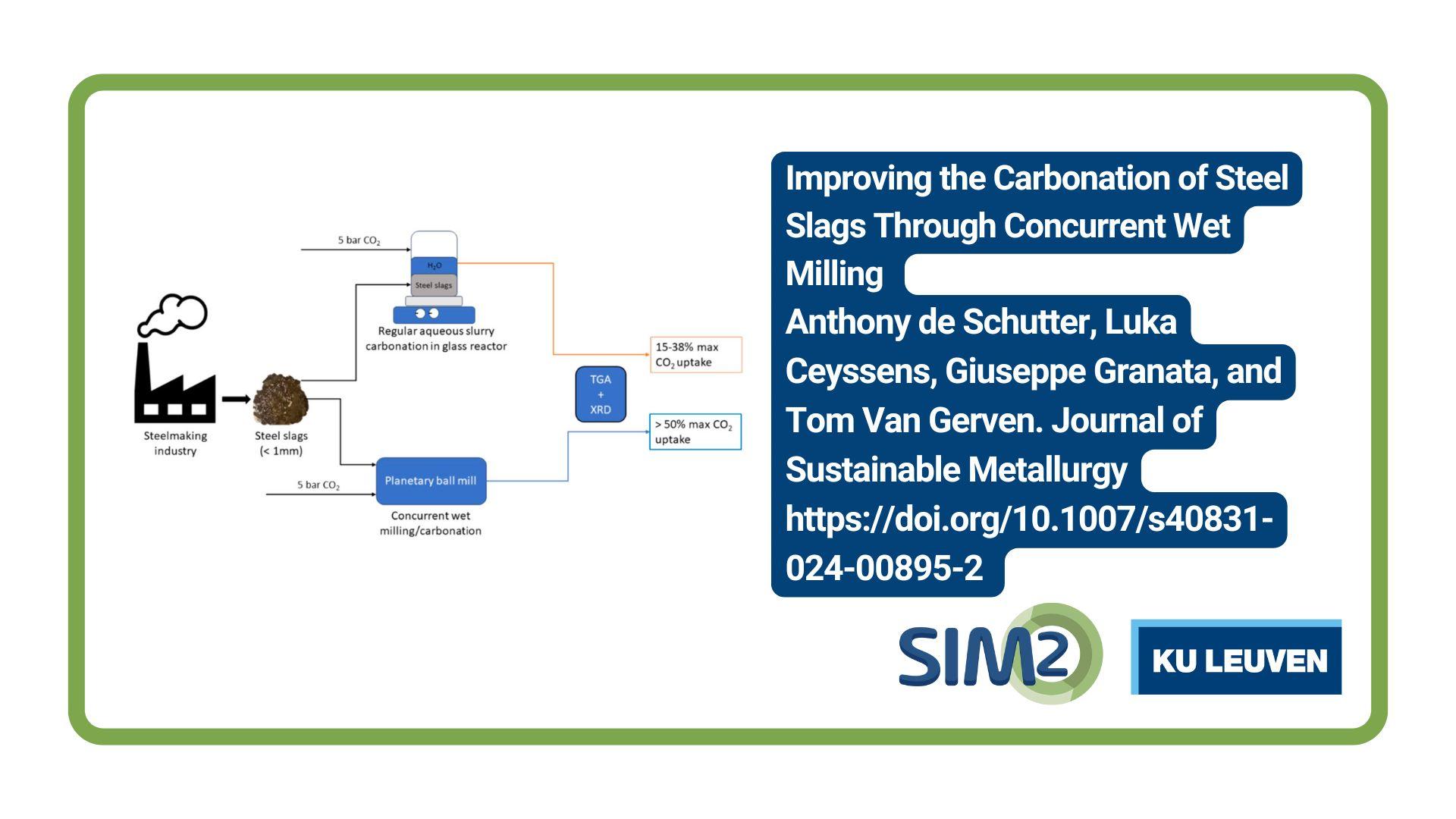

Anthony de Schutter, Luka Ceyssens, Giuseppe Granata and Tom Van Gerven of the Department of Chemical Engineering, KU Leuven, have published a new article on the enhancement of carbonation of steelmaking slags through concurrent wet milling in a planetary ball mill. The article was published on August 12 in the Journal of Sustainable Metallurgy.

This work studies mineral carbonation of steel slags with the aim to reduce the amount of slag that is landfilled. Besides permanently storing carbon dioxide (CO2), carbonating the slags can improve their quality for use in beneficial applications and reduces the leaching of harmful heavy metals. In order to intensify the mineral carbonation process, mechanical activation is used to improve both the carbonation kinetics and yield. The milling is performed in a planetary ball mill which allows for high-intensity grinding, resulting in a fast reduction of the particle size and quick amorphization and disturbance of the crystal structure, allowing high reaction rates to be achieved. The effects of the three main processing parameters of a planetary ball mill—bead-to-powder ratio R , bead size D and milling speed S—are investigated. Under optimal conditions, more than 50% of the maximum CO2 uptake is achieved in only 6 min, representing a very significant improvement over regular slurry carbonation. Quantitative XRD allows to identify the reactivity of the different crystalline phases present in the slag under different milling conditions. With the help of a mass balance, the formation of an inert outer layer consisting of silica ( SiO2) is confirmed. This explains both the shell diffusion mechanism controlling the carbonation reaction and the total conversion being limited to 50–60%.

Reference

de Schutter, A., Ceyssens, L., Granata, G., & Van Gerven, T. Improving the Carbonation of Steel Slags Through Concurrent Wet Milling. J. Sustain. Metall. (2024). https://doi.org/10.1007/s40831-024-00895-2

Acknowledgement

The Research Foundation—Flanders (FWO) is gratefully acknowledged for funding this research as part of the Agri-Carb Project (G0A4821N). KU Leuven Department of Earth and Environmental Sciences is acknowledged for the use of the TGA, McCrone and XRD equipment. Prof. Ruben Snellings is acknowledged for helping with the Rietveld analysis of the slags.