The Life Cycle Engineering (LCE) research group of SIM2 KU Leuven has developed a method that allows to add alloy-level resolution to the Global Flow Model of the International Aluminium Institute (IAI), which tracks and predicts the global flows of aluminium from region to region and throughout the different lifecycle stages. The work was published in the journal Waste Management.

Limitations of the present IAI model

An important drawback of the model used by the IAI is that only the volumes of aluminium are tracked, without any information on the used alloys or the actual composition of the recycled aluminium scrap.

As a result, the IAI model did not consider the technical feasibility of using recycled aluminium in the production of new alloys and the possible emergence of a global aluminium scrap surplus.

Nonetheless, previous research has suggested that, if the current practice of systematic downcycling is maintained, the collected amount of aluminium scrap will soon exceed the capacity of wrought and cast alloys production to absorb the secondary aluminium.

Although this downcycling practice has been a successful strategy in the past due to the high demand for cast aluminium alloys for the production of combustion engines, this is expected to change with the electrification of the automotive industry. As such, it is predicted that a considerable amount of aluminium scrap will be collected for which there is no suitable application, which is commonly referred to as a scrap surplus.

Estimating the global aluminium scrap surplus

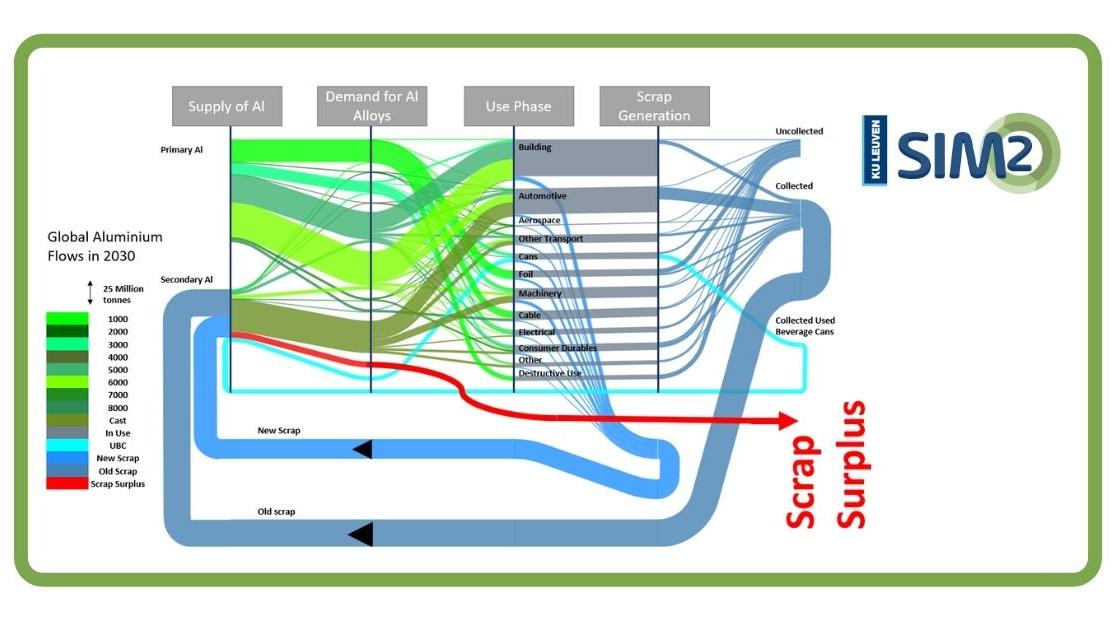

The presented research considers the technical limitations of using aluminium scrap in the production of new alloys. Hence, it also allows to estimate the evolution of the global aluminium scrap surplus in the coming two decades.

The obtained results demonstrate that if existing aluminium sorting and recycling methods are maintained, in 2030 around 5.4 million tonnes globally of aluminium scrap would not be suitable for the production of new alloys. This number is forecasted to grow to around 8.7 million tonnes by 2040.

Towards enhanced sorting systems

This conclusion offers a strong argument for the production and recycling industry, as well as policymakers, to support and invest in the development of enhanced sorting systems for aluminium.

In the framework of the KIC EIT Raw Materials Upscaling project on Automatic Sorting of mixed scrap Metals (AUSOM – https://www.ausomproject.eu/), the KU Leuven Life Cycle Engineering group has demonstrated that it is technically feasible to sort mixed post-consumer aluminium scrap in a way that allows to use a significant share of the scrap for the production of wrought alloys to mitigate the growth of the aluminium scrap surplus.

Future research of the Life Cycle Engineering group will focus on the development of computer vision and spectroscopy-based sorting systems for mixed-metal waste streams. The combination of X-ray transmission, colour, Near Infrared (NIR) and depth imaging with spectroscopic techniques, including X-Ray Fluorescence (XRF) and Laser-Induced Breakdown Spectroscopy (LIBS), is currently under investigation.

The combination of these techniques, and advanced classification algorithms based on machine learning methods for spectral processing have shown promising results for sorting aluminium scrap into fractions that are commercially interesting. These results will be presented at the Life Cycle Engineering 2022 Conference in Leuven: https://lce2022.eu/.

Full reference paper

Simon Van den Eynde, Ellen Bracquen, Dillam Diaz-Romero, Isiah Zaplana, Bart Engelen, Joost R. Duflou, Jef R. Peeters, Forecasting global aluminium flows to demonstrate the need for improved sorting and recycling methods, Waste Management, 137, 2022, 231-240. Reference link to paper: https://authors.elsevier.com/a/1e5wB,LlFPCdm5

More info about the LCE Group

The current research activities of the Life Cycle Engineering Research Group include themes such as life cycle engineering (LCE), product development methodologies, systematic innovation and knowledge management. Recent research was carried out in the area of efficient disassembly techniques to optimise the end-of-life treatment of products; the identification and analysis of energy and resource based environmental and economic improvement potential of manufacturing processes, systematic (biologically-inspired) design as well as in the domain of personalised products through user profiling. LCE is a partner in the KU Leuven Institute for Sustainable Metals and Minerals (SIM² KU Leuven). LCE website: About – Life Cycle Engineering (kuleuven.be)