Sam Haenen and colleagues from KU Leuven have published their latest findings on the effect of adding high-density polyethylene to a polypropylene matrix on thermo-shear degradation in the Proceedings of the 38th International Conference of the Polymer Processing Society. Gel-permeation chromatography (GPC) measurements of polypropylene showed a decrease in molecular weight and dispersity after compounding. Degradation ruptured the longest chains first. Small amplitude oscillatory shear measurements showed good agreement with the GPC results.

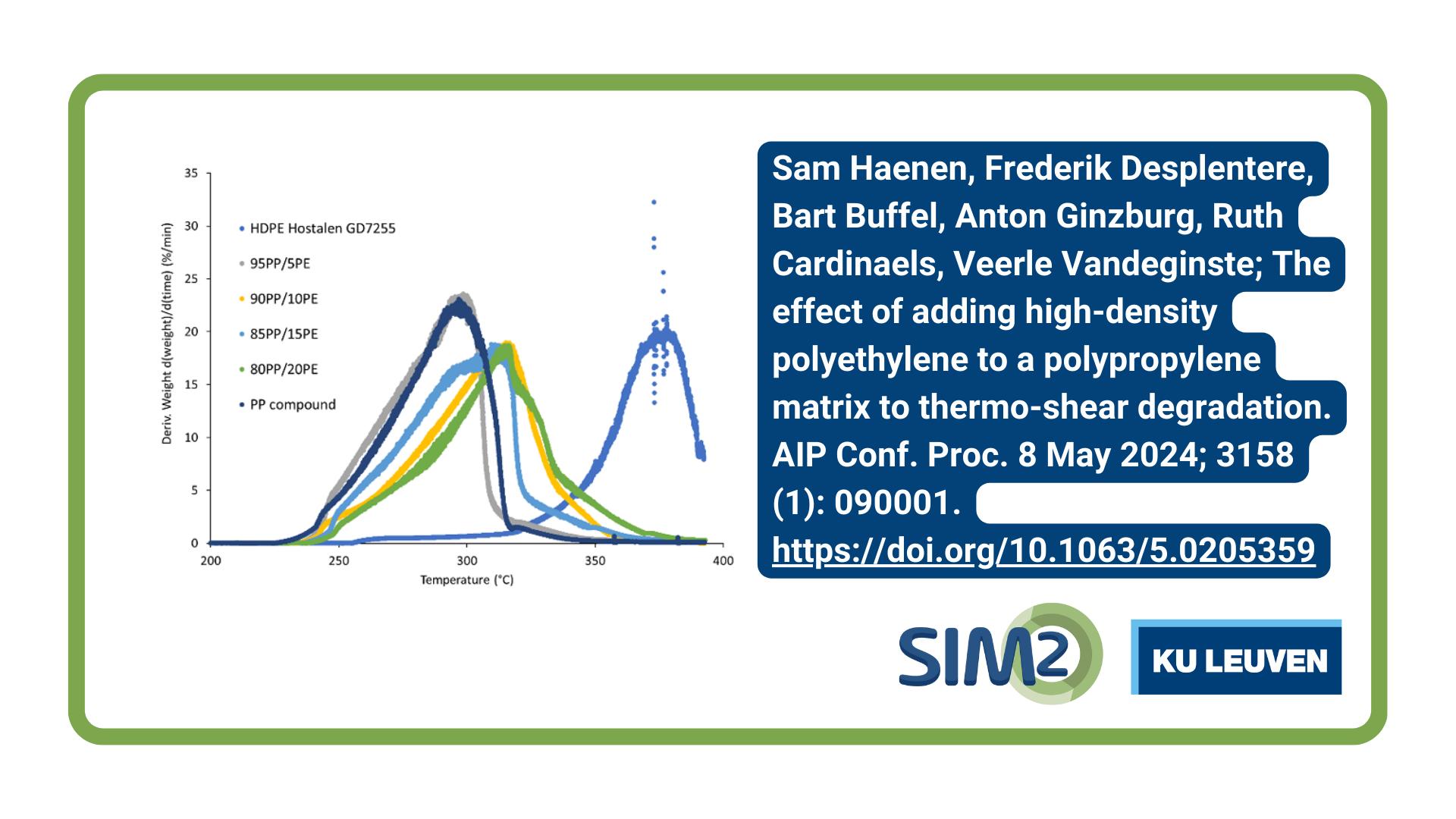

The degradation of isotactic polypropylene (PP) and high-density polyethylene (PE) occurs in an accelerated way during melt processing. Hence, a study of the thermo-oxidative and thermomechanical stability was performed on a corotating twin-screw extruder. First, the origin and effects of degradation were studied. The effect of shear stresses and residence time during compounding on the chemical composition, rheological behavior and mechanical performance was examined. Next, the thermomechanical stability of PP was enhanced by adding HDPE to the PP matrix. Small amplitude oscillatory shear measurements indicated a significant decrease of PP’s viscosity (-40%) after 1 compounding cycle. This was in contrast to PE where no change in viscosity was observed. The viscosity loss was more pronounced in the terminal regime, indicating a higher impact on the long chain molecules due to β-scission reactions. Fourier transform infrared measurements did not show any presence of secondary oxidation products. Thus, thermo-shear was expected to play a dominant role in PP’s degradation mechanisms. The addition of a relatively small amount PE (<20 wt%) to the PP matrix could enhance thermo-shear stability without decreasing mechanical performance. Adding 10 wt% HDPE to PP recovered almost completely the viscosity loss caused by the extrusion processing. However, PE and PP remain two separated phases. Due to low interfacial tension and well-dispersed uniform particle size, no negative influence was observed in the mechanical properties.

Reference

Sam Haenen, Frederik Desplentere, Bart Buffel, Anton Ginzburg, Ruth Cardinaels, Veerle Vandeginste; The effect of adding high-density polyethylene to a polypropylene matrix to thermo-shear degradation. AIP Conf. Proc. 8 May 2024; 3158 (1): 090001. https://doi.org/10.1063/5.0205359