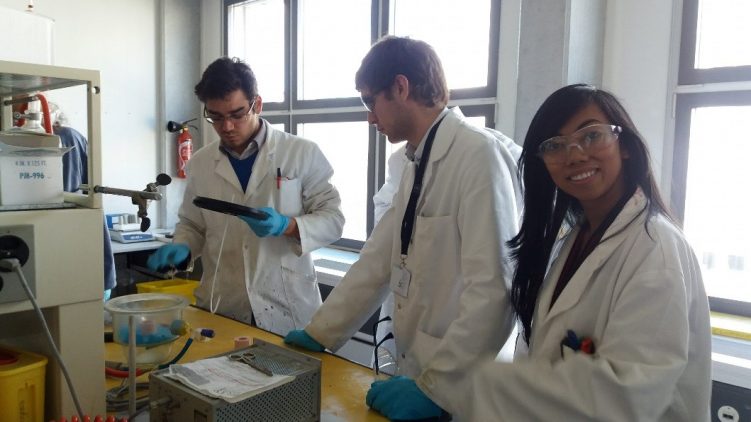

Representing Kerneos Research and Technology Centre (Imerys Aluminates) and the SOCRATES project, I participated in April 2018 to the 4th ‘LC3 Doctoral School‘ hosted by the Laboratory of Construction Materials of the École Polytechnique Fédérale de Lausanne (EPFL). LC3 stands for Limestone Calcined Clay Cement (LCCC, so LC3). The 4-day event was well-attended by PhD students, post-doctoral researchers and professionals from over 15 countries around the world.

It was a great learning experience for cement chemists both on the theoretical and practical perspective. The lectures covered highly relevant topics for my research including: cement hydration, pozzolanic reactivity assessment, XRD and microscopy, mechanical behavior, and durability of cements and concrete. Practical demonstration and exercises were also conducted in the laboratory to impart best practices for manipulations involving cement and blended samples. The doctoral school was concluded with an exam session on the last day to assess the effectivity of the teaching and learning dynamics of the lecturers and participants, respectively.

LC3 (Limestone Calcined Clay Cement), which is on the spotlight of this doctoral school, is a project housed at EPFL and funded by the Swiss Agency for Development and Cooperation through its Global Programme in Climate Change. It explores the viability of a blended cement formulation in the construction application with the aim of reducing CO2 emissions associated with the production of more conventional types of cements. As I am currently working on blended cements incorporating engineered residues myself, I saw that the motivation of the LC3 project is in congruence with my research objectives. Indeed, the methodology and techniques are highly pertinent despite the difference in the formulations.

As a researcher mainly stationed in an industrial partner, I find it beneficial to attend such university-based trainings from time to time to refresh and widen my perspective on different research strategies from an academic perspective. For instance, I noticed some differences in the protocols for sample preparation despite being directed for the same analytical technique between the research center and the laboratory in the university. Understanding the motivation behind the “best practices” in different laboratories promotes critical thinking, going beyond simply following a previously established step by step procedure for an experiment.

Moreover, events like this is also a great opportunity to get on track of the state of the art of my field of research. I got acquainted with various blended cement-related research topics from around the world by having stimulating discussions with the other participants during coffee and meal breaks. I find it more notable to hear about research topics directly from the researchers themselves, more than reading about them in paper. This kind of environment creates a networking opportunity for possible future collaborations. After all, although doing a PhD tends to be easily associated with being independent, I believe that great ideas can come from great minds brainstorming together!

In the next periods of my research, I hope to share the knowledge and skills that I am acquiring along the way to contribute to the academic and industrial community, and to motivate other aspiring researchers around the world. At this point, I can say that it has been truly rewarding from the beginning to be a part of the SOCRATES project!

ESR 11, Jennifer Astoveza, is a licensed metallurgical engineer from the Philippines. She obtained her bachelor’s degree in 2012 from the University of the Philippines – Diliman. She worked as a process engineer in the precious metals plant of the PASAR Corporation, a copper smelter and refinery managed by Glencore-Xstrata. In 2017, she graduated with distinction as an Erasmus+ scholar of the EMerald Programme, an EIT-labelled degree with a specialization in geometallurgy.

ESR 11, Jennifer Astoveza, is a licensed metallurgical engineer from the Philippines. She obtained her bachelor’s degree in 2012 from the University of the Philippines – Diliman. She worked as a process engineer in the precious metals plant of the PASAR Corporation, a copper smelter and refinery managed by Glencore-Xstrata. In 2017, she graduated with distinction as an Erasmus+ scholar of the EMerald Programme, an EIT-labelled degree with a specialization in geometallurgy.

She started her co-joint PhD study between KU Leuven and Université de Lorraine in September 2017, and is directly working at the Kerneos Research and Technology Center (Imerys Aluminates) in Vaulx-Milieu, France. She is tasked to explore the viability of using industrial residues as supplementary cementitious materials (SCM) in calcium aluminate blended cements (CAC).

If you are interested in her research and wish to learn more about it, you can reach her through jennifer.astoveza@kerneos.com