A grasping method has been explored for picking of unknown randomly-oriented objects with a vacuum gripper. The proposed grasping method has been demonstrated to be able to detect feasible grasp regions without requiring the CAD models for the picking of randomly-ordered and stacked Waste Electrical and Electronic Equipment (WEEE). The fast-picking ability and high grasp quality of the proposed method demonstrates great potential for the robotic sorting and dismantling of WEEE. The work, which was performed by lifecycle engineering research group (LCE/SIM² KU Leuven), was published in the journal J. Intell. Robot. Syst.

Virtual vacuum gripper

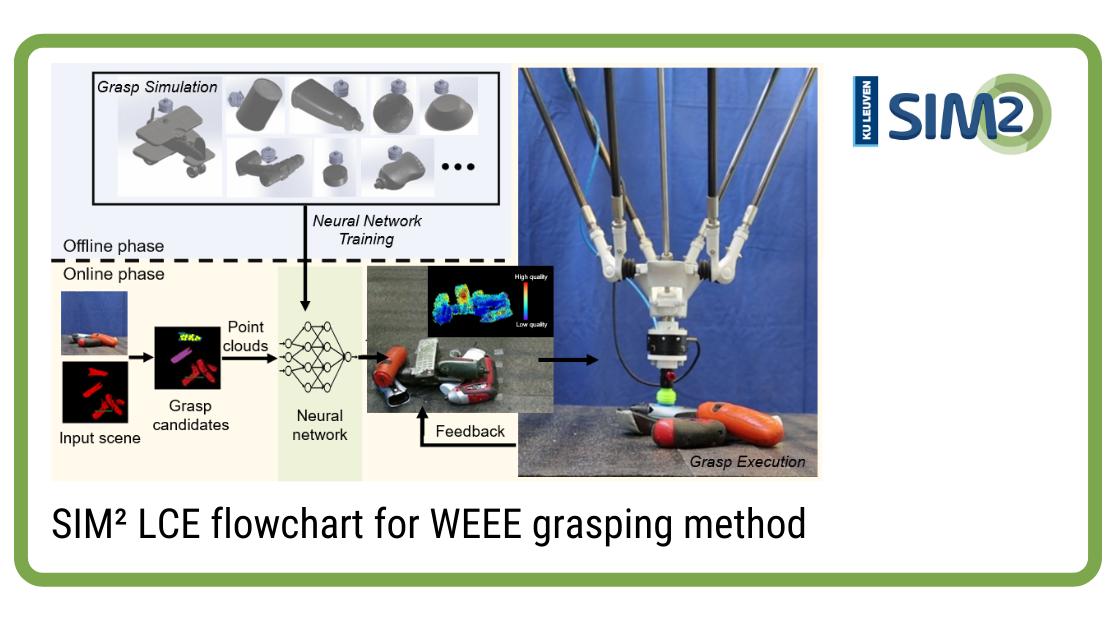

The presented grasping method can be described by two phases: In the off-line phase, a large-scale dataset is synthesized by the grasp simulation with a virtual vacuum gripper and 3D models of objects, which is used to train a Convolutional Neural Network (CNN) to learn the grasp principles for a vacuum gripper.

In the on-line phase, the presented grasping method predicts the grasp quality for the cluttered WEEE using this trained CNN after segmenting the point cloud. The applied CNN uses an 11 11 point cloud as input and provides a predicted value that quantifies the grasp quality as output.

In this manner, a quality map is generated for each product to be grasped indicating the most feasible grasp region. Finally, during the execution of the grasp the 6-DOF force-torque sensor is used to obtain feedback on the grasp status and to adjust the grasp strategy.

Grasping WEEE

Over 6,000 simulations and more than 3,000 physical grasping trails reveal that the proposed grasping method outperforms state-of-the-art grasping methods. It is demonstrated that with the developd algorithm an optimized grasp can be found for WEEE by evaluating over 2,000 grasp candidates within 0.3s, achieving an average success rate of 92%.

Future research in the Automation, Computer Vision & Robotics (ACRO) and LifeCycle Engineering (LCE) research groups will focus on the development of novel gripper systems, real-time grasp planning for multi-robot multi gripper collaboration for grasping objects on a (fast) moving conveyor and on performing durability tests for the grasping of a broad variety of small WEEE.

Full reference of the paper

Zhang, H., Peeters, J., Demeester, E. and Kellens K.. A CNN-Based Grasp Planning Method for Random Picking of Unknown Objects with a Vacuum Gripper. J. Intell. Robot. Syst. 103, 64 (2021). http://doi.org/10.1007/s10846-021-01518-8.

Zhang, H., Peeters, J., Demeester, E. and Kellens K.. A CNN-Based Grasp Planning Method for Random Picking of Unknown Objects with a Vacuum Gripper. J. Intell. Robot. Syst. 103, 64 (2021). http://doi.org/10.1007/s10846-021-01518-8.