The KU Leuven’s lifecycle engineering (LCE) research group (SIM² – KU Leuven) has demonstrated how the data fusion of LIBS spectra and color (RGB) and Depth (D) images can improve the classification performance to a level where post-consumer aluminium scrap can be sorted into commercially-interesting fractions with satisfactory accuracy. This is highly relevant for the recycling industry since such sorting systems encompass the potential to significantly mitigate today’s quality losses during aluminium recycling allowing for more closed-loop wrought-to-wrought aluminium recycling

Aluminium recycling

As a consequence of the electrification and the increased adoption of lightweight structures in the automotive industry, global demand for Wrought (W) aluminium (Al) is expected to rise. In contrast, demand for Cast (C) Al will stagnate. With the growing demand for W Al, there is an increasing need to develop and improve Al alloys' recycling processes that preserve metal alloys at their highest economic value.

Combining LIBS and computer vision systems

In this respect, integrating multi-sensor systems to sort and monitor complex waste streams is one of the most recent innovations in the recycling industry. In the case of aluminium recycling, the complementary strengths of Laser-Induced Breakdown Spectroscopy (LIBS) and computer vision systems offer a novel multi-sensor solution for the complex task of sorting post-consumer scrap aluminium (Al) into alloy groups.

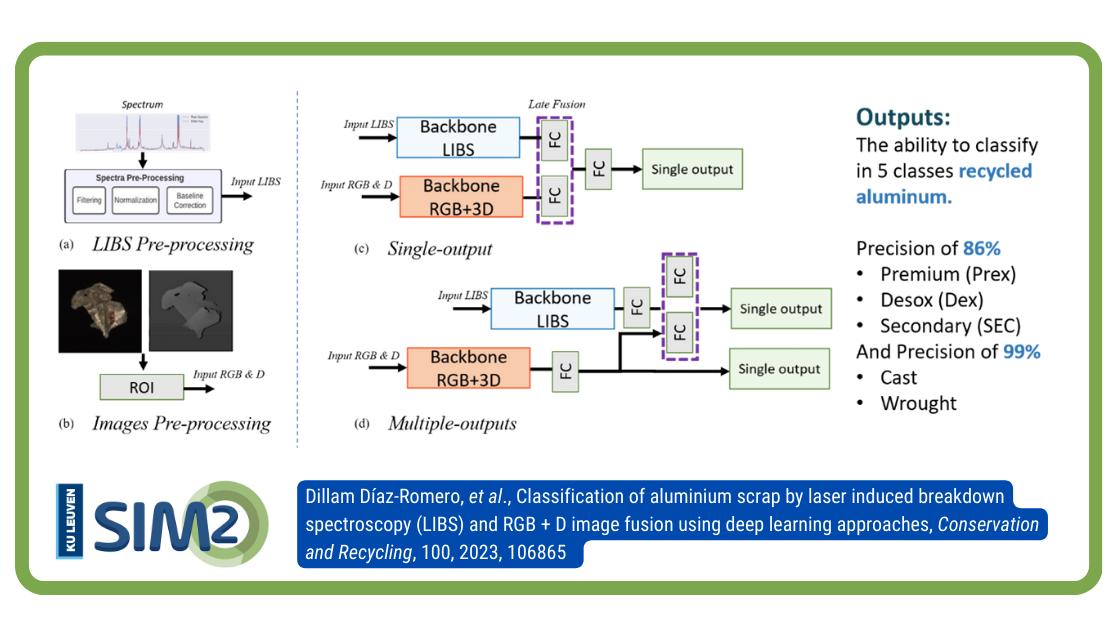

This study presents two new methods for fusing RGB and depth images with LIBS using deep learning models as an improvement of previous work published on deep learning computer vision based Cast and Wrought Al classification (https://www.sciencedirect.com/science/article/pii/S0921344921002949) and LIBS based Al classification (https://www.sciencedirect.com/science/article/pii/S058485472200163X).

The first method developed in recent research is a single-output model that combines LIBS UNET and two DenseNets in a late fusion framework. The second method is a multiple-output model that uses the structure of the single-output model to enhance the model learning and avoid overfitting. In particular, the network has two outputs that enable the regularisation of the individual sensors. A data set of 773 aluminium scrap pieces was created to train and evaluate the developed models with two sets of ground truth-values corresponding to the two envisaged sorting tasks. The first sorting task is separating Cast and Wrought (C&W) aluminium. The second is the division of the post-consumer aluminium scrap into three commercially interesting fractions. The single-output model performs best for separating C&W, with a Precision, Recall, and F1-score of 99%.

The multiple-output model performs best for classifying the three selected commercial fractions, with a Precision, Recall, and F-score of 86%, 83%, and 84%, respectively. With these promising results, it can be concluded that the presented data fusion method encompasses great potential for sorting post-consumer aluminium scrap. By sorting mixed post-consumer aluminium scrap in alloy groups, more wrought-to-wrought recycling is feasible, allowing the mitigation of quality losses during recycling, as is envisioned in a circular economy.

Complete reference of the paper

Dillam Díaz-Romero, Simon Van den Eynde, Isiah Zaplana, Zhou Chuangchuang, Wouter Sterkens, Toon Goedemé, Jef Peeters, Classification of aluminium scrap by laser induced breakdown spectroscopy (LIBS) and RGB + D image fusion using deep learning approaches, Conservation and Recycling, Volume 100, 2023, 106865, ISSN 0921-3449, https://doi.org/10.1016/j.resconrec.2023.106865

LCE research group and EAVISE Research Group

SIM² KU Leuven?

The LCE Research Group is part of the KU Leuven Institute for Sustainable Metals and Minerals. SIM² SIM² KU Leuven’s mission is to develop, organise and implement problem-driven, science-deep research and future-oriented education, contributing to the environmentally friendly production and recycling of metals, minerals and engineered materials, supporting the transition to a climate-friendly, circular-economy.

.png)