Neodymium-iron-boron or NdFeB magnets are a vital part of our tech-driven world because of their excellent magnetic properties and versatility. That is why they are constantly used in numerous appliances from lightweight cellphones and household electronics to maglev trains and gigantic wind turbines. Recycling of these magnets has rightfully gained lots of attention over the last decade. These magnets are rich in critical rare earth elements (REEs) like neodymium and dysprosium, as well as others like cobalt. Although usually ignored, they also contain problematic elements like boron in high concentrations that has to be tracked and controlled. In this work, we propose a novel flow sheet for recycling of these magnets that can simultaneously deliver several benefits.

There are many innovative studies in literature on recycling of NdFeB magnets. In fact, if the viewer is interested, there is a complete website of a EU project (https://kuleuven.sim2.be/category/erean/) with interesting blogposts, news and articles on rare earth elements in general, NdFeB magnets, their recycling and many more.

In this work, we describe an original and green process for the recovery of REEs from resin-bonded NdFeB magnets. The process is a combination of hydrometallurgy and solvometallurgy and can be easily applied to other types of permanent REE magnets too: sintered NdFeB and sintered/bonded SmCo magnets.

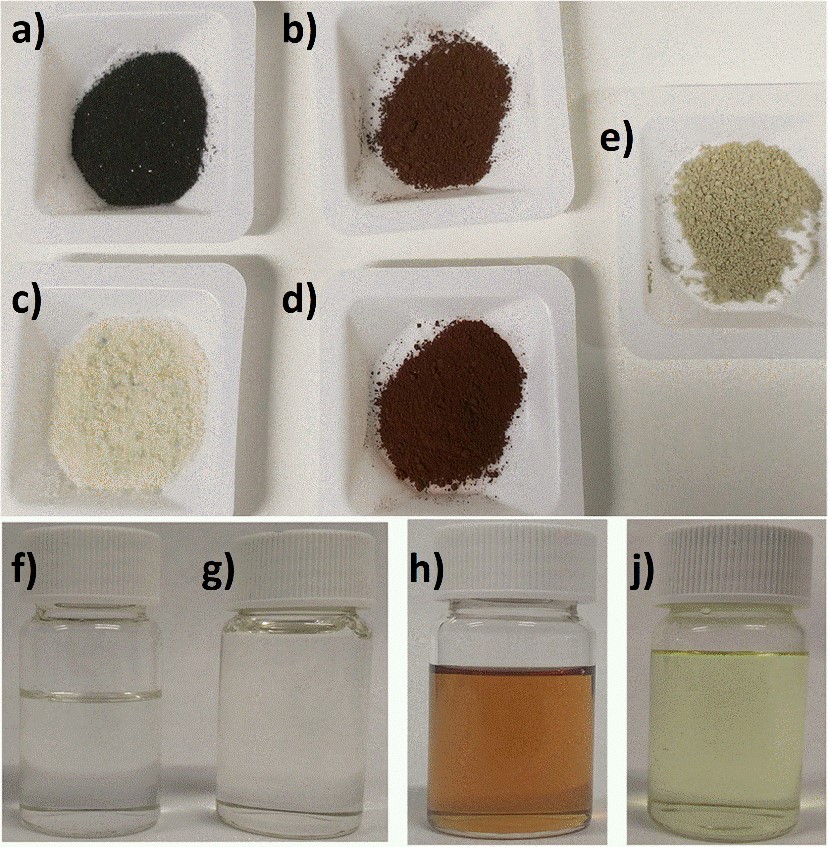

To simulate a real-life situation, the work was performed on a batch of 33 different epoxy-bonded NdFeB magnets collected from several suppliers worldwide. Individual analysis of magnets showed the presence of unusual REEs such as samarium, lanthanum and cerium. The fact that there could be more types of REEs in commercial magnets than usually conceived is an important information especially for separation of REEs via solvent extraction.

With this process, the recovery of more than 90% of boron as useful borax was achieved. Also, more than 96% of the consumed sodium in the process was recovered as sodium hydroxide and sodium carbonate. The recovery of REEs reached more than 95% in several studied conditions with less than 1% iron and 10% cobalt co-dissolutions. After a precipitation stripping step, the consumed organic lixiviant virtually regenerated with same purity. A final mixed rare earth oxide (REO) was produced with 98.4 wt.% purity and minor contaminations from only aluminum and sodium oxide.

Figure 1Images of a) milled magnet batch, b) dried calcine, c) sodium crystallites, d) residue, e) mixed REO and f) depleted, g) fresh and h) loaded Versatic Acid 10 solutions with j) waste oxalic acid solution.

Acknowledgement:

The research leading to these results has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 720838 (NEOHIRE).