Theodoros Dimas, Arne Eggers, Jef R. Peeters and Maarten Vanierschot of KU Leuven, Department of Mechanical Engineering, have published a new article in the journal Engineering Applications of Computational Fluid Mechanics on their work that involves developing and validating of a CFD-based model to simulate rotating-drum separators.

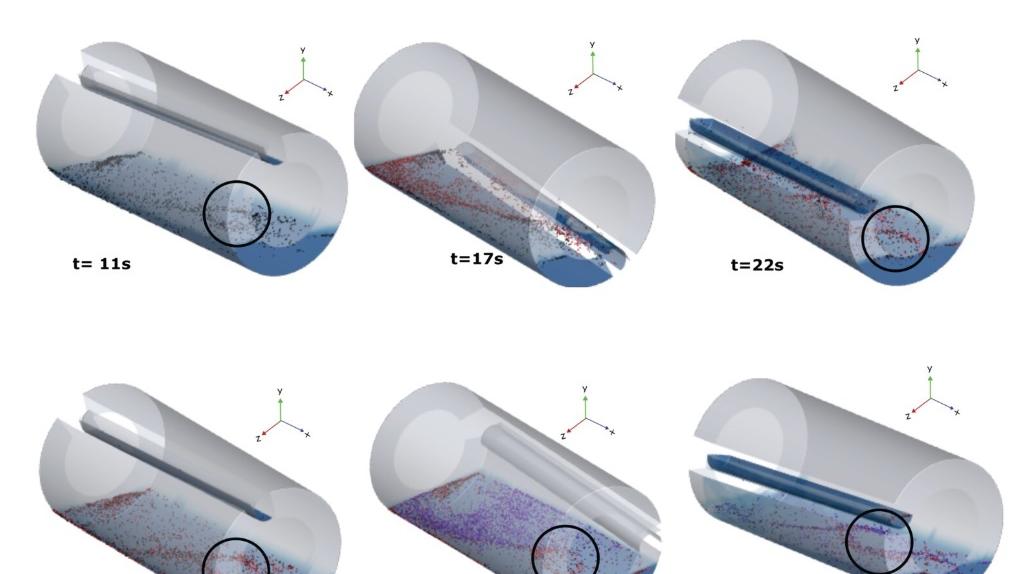

Within the context of the European Green Deal, recycling rates of plastics and metals are targeted to increase which will subsequently increase the requirements for high-quality recycled plastics and metals. The decisive step to achieve this high-quality recyclate lies in the sorting of the materials before their recycling. Density separation sorts materials based on their density difference from a liquid's density and is the most widely used separation technique in the industry because of its high cost-effectiveness. However, experimentally optimising a density separator would require a large amount of time and investment due to its large dimensions and the complex physical phenomena involved. Hence, the scope of this study is to develop a Computational Fluid Dynamics (CFD) model to investigate the fluid flow and trajectories of plastic particles in a density-separation-based rotating drum. This novel strategy and CFD model offer a tool capable of predicting the separation efficiency with an absolute error of 1–5%, depending on the polymer type, while reducing the computational time by a factor of 9. Moreover, the influence of air bubble attachments to the injected particles in the drum is observed and the inclusion of inter-particle collisions on the accuracy of the model is assessed.

Reference

Dimas, T., Eggers, A., Peeters, J. R., & Vanierschot, M. (2024). Development and validation of a CFD-based model for simulating rotating drum separators. Engineering Applications of Computational Fluid Mechanics, 18(1). https://doi.org/10.1080/19942060.2024.2368606

Acknowledgement

The first author would like to express his sincere gratitudeto Research Foundation -Flanders (FWO) to fund this workunder the project number 1S67023N. The authors also grate-fully acknowledge the funding of this research by the FlandersInnovation & Entrepreneurship agency (VLAIO) through theproject Plastics Recycling 4.0 (HBC.2020.2750).